Grinding Wheels

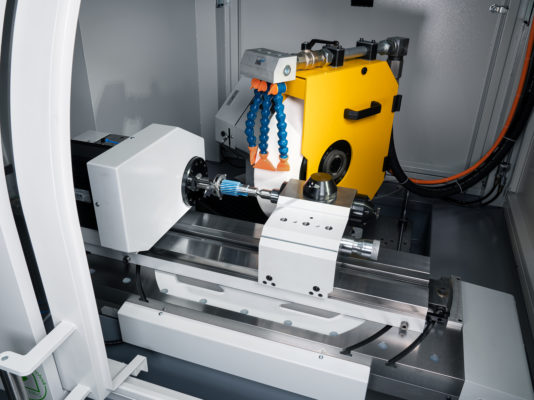

Understanding Bevel Gear Grinding

Key techniques for optimal surface finish and gear quality

Read More

Technology Advances for Continuous Generating Gear Grinding in EV and More

Meeting the challenges of gear grinding with innovative abrasive technology that improves gear efficiency and quality

Read More