NASA's Return to Flight

Jack McGuinn, Senior Editor

On February 1, 2003, the Space Shuttle Columbia and its seven-member crew were precious minutes away from completing the spacecraft’s 28th mission when it literally fell to pieces upon re-entry over Texas. There were no survivors.

A NASA investigation attributed the root cause of the tradegy to a puncture on the leading edge of one of the spacecraft’s wings, which in turn allowed extremely hot air to enter and degrade the wing’s internal support structure. This degradation, exacerbated by the intense heat typically encountered upon re-entering the atmosphere, precipitated Columbia’s disintegration.

But the investigation did not end there. What followed was an intensive, two-year testing-and-analysis period—dubbed Return to Flight—that led ultimately to the successful launch and return in 2005 of the Discovery space shuttle.

GRC chief of space operations Angel Otero is shown demonstrating to a reporter how the center’s work has helped make the shuttle flights safer. Otero oversaw all of GRC’s Return to Flight efforts, to which more than 200 Glenn employees contributed.

Involved in a number of ways during that two-year re-evaluation was the Cleveland-based NASA Glenn Research Center (GRC). Named for Ohio native John Glenn, who in 1962 became the first American astronaut to orbit the earth, the center states its mission as follows: “To work as a diverse team in partnership with government, industry, and academia to increase national wealth, safety, and security; protect the environment; and explore the universe. To develop and transfer critical technologies that address national priorities through research, technology development, and systems development for safe and reliable aeronautics, aerospace, and space applications.”

In clearing the runway for Discovery, that mission was put to the test. And Glenn passed with flying colors. For Angel Otero, chief of GRC’s space operations division, the validation was not unexpected.

“NASA as a whole has come to appreciate Glenn’s expertise in mechanisms, gears, lubrication, high-temperature materials and impact testing and modeling,” he says. “We have been working in these areas for the last 45 years to the benefit of the agency. As a result of the Columbia accident, our capabilities were called upon again.”

And while indeed the center was involved in a variety of test areas—ballistic impact; environment seals compression optimization; on-board repair protocols; and carbon-carbon degradation among them—we will concentrate here on the GRC Shuttle Actuators Investigation Team. Their primary charge was the identification and resolution of mechanical component and lubrication issues in the space shuttle actuators. As is often the case when attempting to identify and explain cause-and-effect issues, the team soon found that one clue leads to another. In this case, an examination of a potential lubrication problem eventually led to gear-specific issues, including fretting and pitting, cycling and dithering.

E-mail launches grease, gears investigation. “How we got involved with the actuators was a very interesting story,” Otero reveals. “When (NASA) was getting Discovery ready for launch they took all the rudder speed brakes out of Discovery, and GRC’s involvement started due to the grease issue. (Editor’s note: Beta testing at the Johnson Space Center in Houston for Discovery had revealed a discoloration and contamination of the grease lubricant in the spacecraft’s rudder/speed brake actuators.) There was a question about the degradation of the grease, and someone in Houston was looking through the literature (technical papers) about questions on grease and he ran into the name of Erwin Zaretsky, who is a Glenn employee.

“And his sending (Zaretsky) an e-mail developed into a two-year involvement for us. First, with grease because we have tribology experts here. But as we started talking it over, it also became a gear issue, with questions about cycling and things like that.”

Space shuttle Discovery makes a perfect early morning landing at Edwards Air Force Base. It marked the successful end of the Return to Flight program, in which the Glenn Research Center played a vital role.

Robert F. Handschuh, an aerospace engineer in the Army Research Laboratory at GRC (and a Gear Technology contributor), was a member of the Actuators Investigation Team. His area of expertise is gears for rotorcraft—not spacecraft—and so the shuttle actuators presented a new, but not insurmountable challenge.

“In general, fretting and wear can result in the loss of gear surface material, and fretting pits can lead to signs of failure; you lose part of the drive capability of the gear tooth at that point,” he says. “Some of these wear mechanisms can snowball and you end up with a system that can’t carry the load. And the shuttle is designed a little differently from, say, your car or a helicopter. We had to think a little differently when we started tackling the problem for the shuttle, but fortunately we have enough expertise here to know that the technology from the aerospace world applies to the space world. It’s just that we were operating in a different zone of the fatigue curve.”

The shuttle has two sets of actuators—the body flap (a thermal shield for the spacecraft’s main engines during re-entry that provides pitch control for the orbiter during its atmospheric flight after entry), which travels up and down, and the tail’s rudder/speed brake. As the latter component’s name implies, it performs two functions. On ascent and descent, it acts like a rudder for vehicle guidance. But upon touchdown, the actuators transform the tail into a speed brake. Otero points out that the danger a failure of that function presents is directly influenced by where the shuttle is to land.

“(If the shuttle) is landing in the desert and the speed brake fails, they just have to chase it down until it stops rolling, because it has its own runway,” he says. “But if the rudder part of it fails, that’s a larger (issue) if they can’t control the flight landing surface (the ocean, e.g.). It’s what is considered a “Crit-1” (Criticality-1) item. It’s very important to make sure that the (actuator) works.

“The engineering thought process was that these (actuators) are not cycled very often—like a helicopter or airplane—because the shuttle doesn’t fly that often; it’s only used on the way up, and again on the way down.

“But one thing that we had not realized was going on was what we call dithering—the way the hydraulic system in the shuttle works. Every time the shuttle was powered up, the actuators were moving basically like a washing machine, just kind of back and forth in place. So that adds a lot more cycles than the original designers had envisioned. Our guys here had to do a test program to simulate the dithering and we made an assessment that, yes, there are more cycles, but maybe not enough to cause a problem.”

Testing needed. But how?

Handschuh points out that the testing and modeling were intrinsically necessary due to the fact that apples-to-apples testing was not an option for the investigative team. That’s because there were no actual, in-use parts to test.“These actuator systems aren’t pulled out routinely, and even the ones that we’ve had access to were pulled out of a shuttle that had flown (only) 30 missions. (The actuators) were designed to last for the life of the shuttle, which is 100 flights or 10 years. And now things have dragged on a lot longer for a lot of these systems. The cycle count of 100 flights hasn’t been as long as they thought, but more years have elapsed.”

To put it another way, think of the way that medical science conducts experimental testing. Testing with humans is often out of the question, so substitutes are used. GRC was the best go-to resource to unravel unknowns because of their state-of-the-art testing and modeling capabilities, some of which are unmatched anywhere in the world.

“Actually, that’s (our capabilities) what drove our involvement,” says Otero. “If (the actuator system) was designed to be taken out (for inspection) after every mission, then they didn’t need to come to us. All they had to do after every flight was open a box, add new grease and, OK—the grease issue is resolved. But that’s a major disassembly that has to occur to get to those actuators. So they needed us to look at it in a lab environment and simulate the conditions so they could get answers without actually having to go in and tear those actuators apart.”

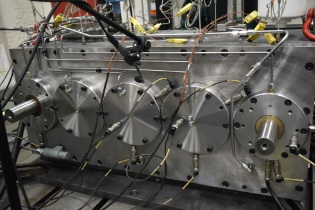

This GRC test rig played a key role in evaluating grease and damage tolerance issues with Discovery’s actuator gears.

The grease and cycling issues presented a number of challenges for the investigative team, among them creating the proper model for simulation purposes, and then extrapolating the results of those simulations to determine with relative certainty whether life- or flight-threatening conditions exist. Keep in mind, these were parts, systems and other components that were designed and built over 20 years ago.

“When they came to us with the grease questions—‘We have this grease and it’s discoloring; what can you tell us about the behavior of Braycote grease and 9310 steel?’—what you normally do is you go to the literature,” says Otero. “And normally, you (cite the technical reports) of a Bob Handschuh, an Erwin Zaretsky, or a Wilfredo Morales (another GRC staffer), and you give them the answer.

“The problem was, there was no literature on a 17-, 20-year lifecycle of a 9310 steel gear system lubricated with Braycote. So we had to start doing aging tests. And by calling (Braycote) we realized they had changed the process of how they made the grease—there was now an older grease and a newer product—so our tribology guys had to test all those things here in order to determine that, yes, the grease is discoloring and decomposing a little. But it really didn’t impact the relationship between it and the gears.”

Determining that the grease was not severely impacting functionality was a relief to all concerned. That’s because—given that the current shuttle program was nearing the end of its intended lifespan (2010)—finding and qualifying a new grease was not a realistic option.

“When things like a grease get space-qualified, it’s like they’re cast in concrete,” Handschuh explains. “ ‘Thou shalt use it until this vehicle is done being used.’”

“Making a grease change on the shuttle would be a big job and cost a bunch of money to get everything re-qualified,” Otero adds. “First you’d have to find the grease that does the job and then be able to figure out what is the proper qualification program. Remember that with the constraint that the shuttle is to retire in 2010, the realization is that if it is going to take four or five years to get a new subsystem qualified, it doesn’t make sense to try and change it.

“This grease had a history of not having failed, so they wanted us to make sure that there wasn’t anything that they were missing by having those gears lubricated with Braycote. And the answer was ‘no,’ as far as we could tell. But if that grease were to stay in there for another 20 years, then you start asking questions again. But the reality was that it wasn’t going to happen.”

From there, it was on to the actuators’ dithering/cycling issues. Were the actuators a “GO,” or not? Again, model simulation testing and analysis was required.

“We did dithering testing; we converted one of our contact fatigue rigs to do the dithering motion to check for gear surface wear,” says Handschuh. “And we did some work on single tooth bending, and at some pretty high loads. We were looking at low-cycle fatigue behavior of 9310 steel and we will probably be presenting a report this year at the ASME (International Design Engineering Technical Conferences) in September.”

Testing and verifying probability.

But to really get their minds around the gear questions, the team employed probabilistic analysis to best determine the lifespan and reliability of the actuators. In other words, with what certainty could the investigators determine the probability of either the efficacy or malfunction of the actuators? The answer, says Otero, is test and verify. Often.

“The simplest explanation is that one test is not enough. That’s something we had to explain to the program because they were always saying, ‘OK, we’ll do one test and you tell us if the gears are OK.’

“I have a sign on my desk that says ‘One test isn’t worth 1,000 experts’ opinions.’

“If you do just one test and pick the one bad one (outlier, or misleading, data point) in the set, you’ll be giving them a bad answer. Or if you pick the one good one in the set, you might also be giving them a bad answer. You have to do enough tests to show that your scatter (variance) is within the band that they’re worried about. If you do only one test you might be getting the one outlier data point. We were asked that if we were shown old actuators that were made at the same time as the ones that are in orbit, could we tell them if the ones in flight were okay.”

Otero points out that looking at one set of gears might result in overly optimistic conclusions, or, conversely, in a great deal of unnecessary work and cost. Either way, an incorrect finding can lead to significant—if not fatal—consequences.

“If you just look at that one (bad) one and it happens to be the one outlier point on the backside, you go through this whole test program unnecessarily. Or worse, if you look at it and it happens to be a good one—but it might not be where the majority of data is going to be—you might give them a false sense of security. In a probabilistic situation you have to do enough tests to build enough data to be able to answer the question properly.”

Dr. Robert Handschuh, an aerospace engineer in the Army Research Laboratory at GRC and member of the Actuators Investigation Team. An expert in rotorcraft, Handschuh was able to adapt and apply his skill in that sector in order to help conduct critical evaluation of

the actuators’ grease, fretting, wear and

dithering issues.

Upon completion of all the necessary modeling, simulating, analysis and other testing, the conclusion of the investigative team was that the lubrication and actuators issues were resolved to everyone’s satisfaction, and no further work was required specific to operations in the final years of the 26-year shuttle program.

As one of NASA’s 10 field centers, the invaluable work the GRC performed for the Return to Flight program helped the agency get back on track with the successful Discovery flight in 2005. But aside from that specific task, the center conducts ongoing research and testing that will enable NASA to go forward with space exploration.

And while it is commonly known that the technology developed by NASA often finds its way into any number of general-use applications, that synergy is sometimes reversed. The automotive industry’s influence on rotorcraft is a surprising example.

“Actually, the people on the automotive end have been getting closer to being at an aerospace level of technology in their manufacture of what comes out on your car,” says Handschuh. “We go to the same (conferences) that people from the automotive industry attend, and our technology transfer to report writing is how we distribute results.

“Some of the people from the automotive arena can teach us, too. They do some interesting things in the automotive world now that we hopefully can apply to things for our helicopters in the future. They (automotive transmission designers) are real sensitive to noise—you don’t want a noisy transmission in your car—and there’s some technologies they’ve really pushed hard. In fact, some of the leading researchers in our country doing gear technology have backgrounds in automotive.”

But let’s face it: It is rocket science, after all, that most excites the imagination and sense of wonder in many of us. And perhaps that is best summed up by NASA’s stated vision:

“To improve life here. To extend life to there. To find life beyond.”

For more information:

NASA Glenn Research Center

21000 Brookpark Road

Cleveland, Ohio 44135

Phone: (216) 433-4000

Website: www.grc.nasa.gov