Helix Wiper Geometries Reduce Vibrations and Increase Tool Life

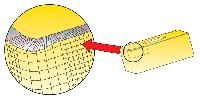

Seco Tools Inc. recently unveiled Helix wiper geometries for operations in high-feed machining of case hardened steels where standard wipers cannot be used. According to the company’s press release, the Helix concept is designed to reduce vibrations, increase tool life and increase the number of parts produced per cutting edge. It has wipers on both sides of the corner radii that are standard, but the protection chamfer is twisted from negative to positive or positive to negative.

Seco’s wiper geometries enable the operator to obtain a smooth surface by lessening the effect of the workpiece feed pattern created during conventional turning. Helix wipers are available in brazed format CBN050C or a coated low-CBN grade.

“Reduction in production time along with the near doubling of tool life equates directly to significant savings in total production costs,” says Henrik Sandqvist, Seco Tools Inc. product manager of advanced materials. “The result is better than that of conventional case-hardened steel finishing where slower speeds and feeds are typical and additional grinding processes are often required.”