Gear Expo Preview: Reishauer Booth 239

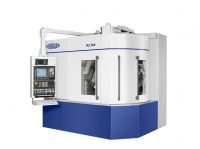

"We plan to exhibit the RZ 260 Two-spindle Gear Grinding machine that can be used for high production runs utilizing the continuous generation style of grinding or for small lot sizes or parts with features that don't allow the use of a large diameter wheel using the single index or form grinding technique," says Dennis Richmond, vice president. "Also on display will be the small spindle which allows the machine to use wheels as small as 60 mm. Our booth wouldn't be complete without an array of diamond and CBN tools that Reishauer has become well known for when it comes to accuracy, quality and usable life.

The RZ 260 is available in four versions. In the basic version, the RZ 260 is equipped with one work spindle. For loading, this is automatically moved into a well-accessible loading position. For very high productivity demands, the machine can be equipped with two work spindles. In this configuration, the ground gear can be exchanged while another gear is ground on the second spindle. The machine is equipped with a fixed dressing unit if only a small variety of gears is ground. Different gear geometries can be ground using workpiece specific dressing tools. Maximum flexibility can be reached by using a pivoting dressing unit. With this version, the dressing tools can be used for a larger range of gears.

"Visitors to booth 239 will also learn about our newest alliance with Felsomat, a company specializing in gear manufacturing cells (machines and automation) that eliminate idle time, dramatically reduce floor space and offer exceptional productivity for high volume applications," Richmond adds.