IMTS Preview: Dontyne Systems

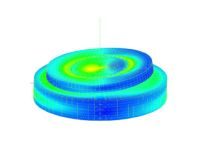

Dontyne Systems has developed a Gearbox Model to simulate deflection of a fully coupled system of gear, shaft and bearing components including the housing. The tool can utilize FE data from 3rd party software. Deflection data can be passed directly to the tooth contact analysis module Gates to provide a substantial improvement for the existing customer base. Detailed component design can be called directly within the model. Further development will see planetary systems and NVH analysis possible. Dontyne has integrated MESYS AG calculations for shafts and bearings with a significant increase in the capability of the Gear Production Suite. MESYS bearing calculation considers the load distribution in the bearing and therefore can take into account operating clearance, tilting angle or moment load. The shaft calculation uses the resulting non-linear bearing stiffness and is therefore suited for statically indeterminate systems.

"We are very excited about the relationship developing with MESYS," says Mike Fish of Dontyne. "The software produced by MESYS is of high quality and fits precisely with our strategy. As with our own approach to gears, the new software calculates according to standards but also give access to higher level of detailed analysis required for high performance applications. We are also well aware of the pedigree of MESYS to be sure of providing the fast and flexible support for our customers."

"Considering housing stiffness, bearing clearance and stiffness and automatic calculation of shaft deflection will increase the accuracy of inputs for TCA," says Markus Raabe of MESYS. "Like the integration of MESYS shaft and bearing calculation in Dontyne software, parts of Dontyne gear calculations and TCA should be accessible from MESYS software in the future."

Renishaw continually develops its MODUS metrology software application to meet the demanding requirements of customers in a global market. A joint development with Dontyne Systems has resulted in the release of MODUS Gear and MODUS Spline software. The gear metrology expertise from Dontyne and the applications experience of Renishaw was an ideal combination to produce software that offers a high level of functionality and exploits the benefits of Renishaw's coordinate measuring machine (CMM) scanning systems.

Eaton and Dontyne Systems have completed the improvement and integration of design and manufacturing software to significantly reduce product development time in the production of bevel gear systems. The dramatic improvements have demonstrated Dontyne's ability to deliver complex development in a relatively short time frame. Tom Riley of Eaton Corporation said of the collaboration, "Dontyne's software brought us a huge improvement in productivity: reducing hours of work to seconds. The visual representations make the software very intuitive to use and understand, and the results are quite accurate. The endeavor was so successful that more collaboration is inevitable."

"We were delighted to work with Eaton on the recent project, and very happy to hear about the significant improvements in production enabled by the development," Fish said. "This has once again proven Dontyne can deliver customer specific requirement to utilize a large internal knowledge base of design and machining procedure, which can be developed as a stand-alone program or integrated to our off-the-shelf design and analysis tools in the Gear Production Suite if required." This and other developments at Dontyne will be discussed during IMTS in Chicago.