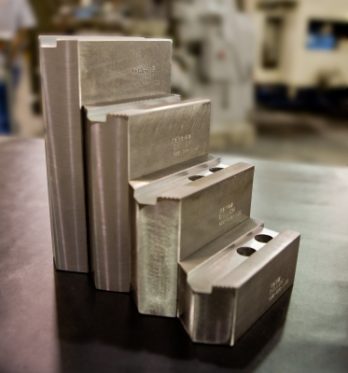

Dillon Now Offers 1018 Steel Jaws from 1 1/2 to 10 Inches Tall

DMI Series H extra-high chuck jaws from Dillon Manufacturing provide extended jaws lengths with heights available to 10-inches tall. The longer lengths can provide greater work piece stability, plus multiple uses of the blank before it is consumed. The extra length also allows the machinist to avoid additional time and costs associated with the welding and bracing needed to lengthen a standard height top jaw.

Manufactured from 1018 steel, 4140 steel, or 6061 aluminum, these extra high jaws are available in all standard chuck mounting styles. DMI Series H, extra high jaws are ideal for precision boring, tapping, drilling and finishing.

With production capabilities to produce large runs of special jaws with the same speed and accuracy as small runs, Dillon is uniquely qualified to handle any jaw manufacturing request. Their applications department routinely works with customers to modify jaws from an extensive catalog of existing designs, or manufacture custom jaws from supplied customer specs/drawings. Dillon uses optical checking to check for more than just simple dimensions. Length and width measurements, for example, can be quickly obtained from two separate measurements by using a micrometer. These superficial measurements, however, might not reveal burrs, scratches, indentations or undesirable machined characteristics of a part. Such imperfections are detected on the DMI comparator.

ISO registration insures a solid quality management system that is capable of producing consistent, high quality jaws at competitive prices.