Gleason Inspection System Offers Key Measurements on Single Platform

Gleason Corporation’s new 300GMSL Multi-Sensor Gear Inspection System will have its European première at the Control Show in Stuttgart, Germany May 9 - 12, 2017.

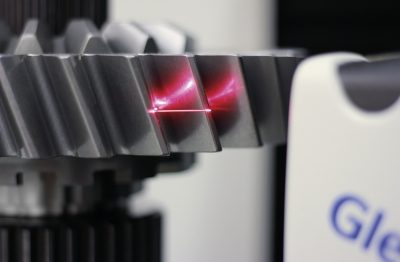

The versatile platform of Gleason’s 300GMSL Inspection System provides the classic tactile probing methods for inspecting conventional gear data on spur and helical cylindrical gears as well as straight, spiral and hypoid bevel gears with a diameter of up to 300 mm. In addition, the new inspection system allows non-contact laser sensor scanning of tooth flanks to support gear development. Complete topography data can be recorded far more rapidly than with conventional tactile probing, with comparable results.

The integration of laser scanning and associated 3D graphics with CAD interface considerably expand both the functionality and the range of applications for this machine platform. The new option makes the 300GMSL the ideal solution for research and development applications for both prototype and production parts or when reverse engineering is required. The 300GMSL Inspection System is also an ideal fit for rapid measurement of topography in regular production operation and satisfies the increasingly stringent requirements on gear inspection. Compliant, soft materials (such as plastic gears, for example) can be inspected without sustaining damage.

Further options such as surface finish measurement or Barkhausen noise analysis to inspect grind burn reduce operating costs, annual maintenance and certification costs and space requirements by offering multiple technologies on a single machine platform.

Another highlight at the Control Show in Stuttgart is the 300GMSP Analytical Gear Inspection System which was designed for use directly in the production environment and which yields reliable measured results in demanding environmental surroundings. To achieve this, the 300GMSP has integrated systems to compensate for temperature fluctuations and to dampen vibration in the production environment. The 300GMSP is especially suitable for applications in the aerospace and automotive industries, but of course also well suited for the inspection of high-quality gears in other sectors of industry.

The Closed-Loop Function, available for many years in bevel gear production and developed by Gleason for cylindrical gears in 2015 for direct transmission of measured data to the production machine, is part of the standard repertoire of the GMS series of machines from Gleason Metrology Systems.

The inspection systems presented will be accompanied by high-precision workholding solutions for metrology applications to boost measuring efficiency to the next level.

(Gleason and GMS are registered trademarks of The Gleason Works, All Rights Reserved)