DVS Technology Group Presenting Gear Grinding Solutions at EMO

The EMO fair booth of DVS Technology Group in Hall 17, Booth C46 will be focusing on the high-precision machining of components for powertrains of the future. The company group, whose member companies supply machines and tools for the fields of turning, gear cutting, grinding and gear honing as both individual and system solutions, will be presenting a total of three new machine platforms, a new face grinding technology and numerous innovations from the machine and tool segment at this year's EMO in Hanover.

Diskus Werke Schleiftechnik GmbH is introducing the face grinding technology DDG - Diskus Defined Grinding - at the world's leading trade fair. This new technology permits users to precisely define material removal on shouldered and non-shouldered faces. The technology is being used on the new machine platform DFine. This way, the interaction between machinery and technology opens up a host of new possibilities in terms of the perpendicularity of machined faces to reference diameters. In the same way, defined axial step dimensions of shouldered faces can be ground on one or two sides. An adjustment option on the workpiece carrier allows flat surfaces to be ground either concave or crowned. The micrograph can also be specifically influenced. With a footprint of only 3m², the DFine is extremely compact and can be concatenated or automated easily and at low cost by means of a belt feeder.

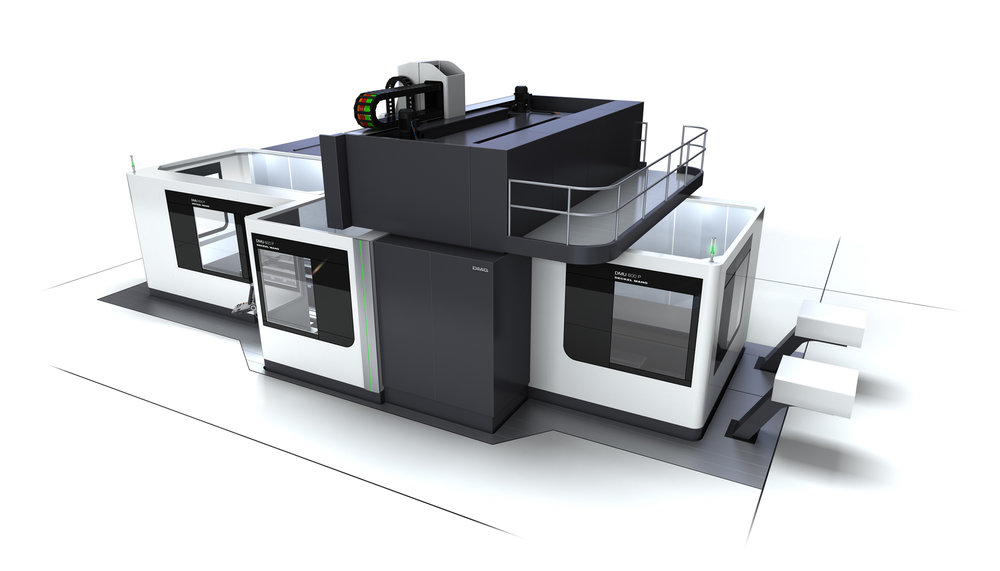

For EMO, Pittler T&S GmbH will be offering the first skiving centre of its kind including automation cell for the complete machining of larger components with a diameter of up to 400 mm. Based on the tried and trusted Pittler vertical series, the new SkiveLine platform has been oriented towards the advanced Pittler Power Skiving gearing technology, which can be used for both the internal and external gear cutting of components. Components such as the hollow wheels of the planetary gearbox which will be installed more and more often in drives in the future can either be machined completely with one clamping or be machined by upstream or downstream turning, milling or deburring processes in addition to gear cutting. The Pittler SkiveLine has also been optimized for fully automatic series production. The work chambers of up to two gear centers are automatically supplied with tools via an innovative automation cell, thus minimizing space and investment requirements compared with robot loading. This allows manufacturers to react economically to varying batch sizes, which is not possible with sequential machining on several machines.

Buderus Schleiftechnik GmbH will be presenting the trade public in Hanover with an innovation combining the best of two machine worlds in the form of the new machine platform BV235. An enhanced modularity has resulted from the merging of the special design and technology features of the machine platforms CNC235 and DVS ModuLine. The increased demands made by customers on tool shapes and finishes can thus be implemented with combined machining processes, optimized in terms of cycle times and in reliable processes. This is also why Buderus Schleiftechnik has integrated the technology of borehole honing into the process chain at grinding and turning operations within the context of combined hard machining and finishing in one machine.

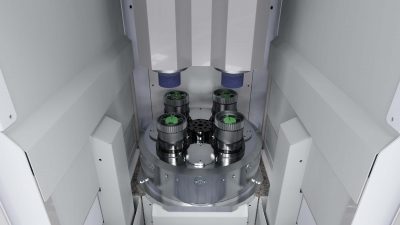

Präwema is exhibiting hard skiving and internal honing for the first time. All there is to know about the gear honing of transmission components will be demonstrated by Präwema Antriebstechnik GmbH at the DVS booth. Experts within the branch are predicting that the quality of gearing will have to be optimized even further in terms of load-bearing capacity and NVH-behavior in view of the development of electric drives and the higher rotation speeds to be expected. Präwema offers complete gearing solutions from soft to hard machining and finishing both for internal and external gearing. For the gear cutting of hardened passenger car transmission components with an average quality requirement, Präwema is highlighting hard skiving for series production at the EMO. For internal gearing with significantly higher quality requirements, the Eschwege-based company has further developed the technology of internal honing. For the first time, hardened, and thus more stable, gearing in terms of pitch values and surface structure have been able to be significantly optimized as a result. For direct comparison and in order to illustrate the modularity of the SynchroSkiver machine series, Präwema is demonstrating both methods in one work chamber at the EMO.

Präwema is also using the EMO to present new developments for outer gearing. VarioCrossHoning - a special oscillation method during honing - makes it possible to reduce surface roughness even further and thus further increase the surface quality of components with external gearing. The method can be marvelled at for the first time at the EMO together with the new, larger honing head with a diameter of 400 mm for components with a maximum diameter of 220 mm.

DVS Tooling GmbH will be presenting a comprehensive spectrum of tools for Präwema gear honing for both internal and external gearing in Hanover. The dressing tool VSD SF is new in the range. In this case, the letters SF stand for "superfinishing" and refer to the extremely good surface quality. To do justice to these requirements in series production as well, the tools used must be coordinated accordingly. With the VSD SF, DVS tooling has managed not only to offer tools with extremely tight production tolerances, but also surfaces of Rz < 1 µm for external gearing.

A further DVS Tooling highlight for the EMO will be the diamond dressing gear wheels which the company finishes using its own DVS LaserCut method at its base in Hemer near Dortmund. The diamond wheels from DVS Tooling GmbH thus stand out with great cutting properties, excellent pitch quality and a long service life.

Within the DVS Technology Group, one company is dedicated to the complete machining of shaft components - Werkzeugmaschinenbau Ziegenhain GmbH or WMZ for short. At the EMO, the focus of the WMZ exhibits will be on the machining of components for alternative drives: the motor shaft of an electric drive will be soft turned, milled, drilled and geared using the power skiving method on an H200 machine live at the fair. With this technology combination, WMZ is primarily addressing production companies with medium-sized series for the electric vehicle industry.

The DVS UGrind on show at the fair booth can carry out the hard machining and finishing of small to medium-sized series of identical components precisely and in a reliable process. Faces and plunge cuts are made using hard turning. Outer diameter, sealing and key surfaces are ground with high precision. Then a specially integrated honing unit finishes the bearing seat of the hollow shaft, achieving a surface roughness of Rz < 2.5 µm. The key feature of the machine is the flexible multi-functional head which has an activity radius of 270 degrees. Through this head, all tools as well as a precise measuring sensor are used with short travel and a high efficiency factor.

A further area of application for the DVS UGrind is classic workshop production, where a large range of different shaft or lining parts are manufactured in different, usually small, batch sizes. And it will be precisely this range of components that is machined live in authentic surroundings at the booth in Hall 17.

Naxos-Diskus Schleifmittelwerke GmbH will also have several innovations on display at the booth. The company is presenting the new Airmento binding for cold-pressed CBN grinding discs for double-sided face grinding. The newly developed binding stands out thanks to its optimized bonding strength, temperature resistance and enhanced damping behavior during grinding. Correspondingly longer tool service lives, improved conditioning ability as well as higher supply and feed rates for optimized material removal rates are the result.

The DVS Technology Group fair booth is located in Hall 17 Booth C46.