The ANCA Group Celebrates 50th Anniversary at U.S. Headquarters

On May 7-8, 2024 in Wixom, Michigan (Detroit), the team of the North American operation for Australian-based ANCA Group, a global leader in grinding machines and automated manufacturing technologies, celebrated the company’s 50th anniversary with company founder Pat Boland. Founded in 1974 by Boland and his partner Pat McCluskey, the company is today a world-class supplier to the major auto, aero, medical, electronics, woodworking, and other market segments in the industrial world. Russell Riddiford, a longtime ANCA associate, heads the North American operation. At the event, the company welcomed hundreds of customers and business associates, as well as the Australian Consul General Chris Elstoft and Cody Schaub, a representative from the office of Michigan Congresswoman Haley Stevens. Stephen LaMarca and Chris Chidzik from AMT delivered the keynotes.

Pat Boland, ANCA co-founder, remarked, "For 50 years, ANCA has been on a journey to change the shape of the cutting tool industry. To celebrate our 50th anniversary, we look forward to meeting with our customers and partners at celebrations being held at our global facilities. As innovation has motivated us throughout our history, new products and developments will be at the center of all these celebrations. ANCA’s future is exciting, we are focused on continuing to invent and deliver groundbreaking technology to help take cutting tool production into areas not previously thought possible.”

During the event, Russell Riddiford presented a fully refurbished TG4 tool grinder to Pat and Libby Boland. The TG was an early generation of machine for ANCA, and this particular one was the third of its kind and the first sold in the US. The machine will be displayed in the company’s booth at IMTS in Chicago, September 9-14, then returned to the company’s headquarters in Melbourne, Australia.

A number of ANCA business partners were in attendance at the event in Wixom, including Arobotech Systems, Blaser Swisslube, Ebbco, Continental Diamond Tool, CemeCon, ACEL Leasing, TechMet, Rush Machinery and Zoller.

Russell Riddiford commented, “We were very honored to have Pat Boland join us to celebrate this milestone for ANCA. His vision for the company remains our benchmark of success and our inspiration to do more for our customers, with machines, software and manufacturing automation technology. Plus, as good Australians, we love a party,” he mused.

Russell Riddiford of ANCA (right) speaks with Australian Consul General Chris Elstoft (left) and Cody Schaub from Michigan Congresswoman Haley Stevens’ office (center).

The ANCA team with founder Pat Boland (front row center)

(l to r) Russell Riddiford, Pat Boland, Libby Boland of ANCA

The team from Midwest Accurate Grinding, who bought the first TG machine sold in the U.S. by ANCA, with Pat Boland

Australian Consul General Christ Elstoft addresses the gathering

Among the other ANCA technologies discussed during the event:

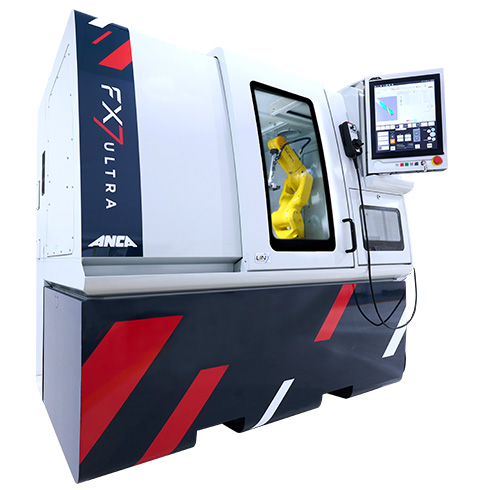

ULTRA Technology: the platform for highest precision and micro tool work

Revolutionary ULTRA technology combines nanometer control, servo-controlled algorithms and mechanical stiffness upgrades to achieve unprecedented accuracy. The FX7 ULTRA and MicroX ULTRA demonstrate ANCA's commitment to precision, enabling continuous batch production down to 0.03mm and setting new standards in tool manufacturing.

The MicroX ULTRA premiered at EMO 2023 and was released to the market at GrindingHub, giving micro tool manufacturers all the advantages of the ULTRA technology and ANCA’s Machine Intelligence in a unit tailored to this application. As the only micro tool grinder with nanometer control, optimized mechanical layout and axes travel, integrated tool measurement and progressive automation, this six-axis grinder is the ideal solution for volume production of tools down to 0.03mm.

50 years of innovation and “thinking outside of the box”

ANCA started with a minicomputer and teletype installed at co-founder Pat Boland’s home, followed by a CNC and then the design and manufacture of machine tools with co-founder Pat McCluskey. Throughout the years, ANCA has brought significant advantages to the industry with pioneering innovations like the first touch probe, soft axes and 3D simulation.

Naturally, software and automation are key highlights of ANCA’s anniversary innovation portfolio. The latest version of ANCA's ToolRoom software, RN35, offers:

- Average performance increase of up to 20% with advanced features and functions, optimizing feedrate, improving cycle time and surface finish, while extending wheel life.

- New developments including the integration of material removal rate calculations, allowing manufacturers to automatically set parameters for constant removal rates, plus air-time reduction.

- Statistical Process Control (SPC) software for statistical analysis and evaluation of manufactured part characteristics streamlines manufacturing processes.

- Profile fluting further enhancing the popular flute from solid feature of the proprietary ANCA software.

The Future of Automation in Tool Production IS here today…AIMS

The ANCA Automated Manufacturing System (AIMS) is a highly integrated, advanced automation system that brings together machining, metrology and materials handling plus data management in a leading-edge ecosystem for a lights-out production of tools used in myriad industries.

With AIMS Connect, recently debuted at GrindingHub in Germany, visitors can experience firsthand the power of digital production control and modular automation, now available for existing installations. The system has proven in the field that it empowers manufacturers to explore new opportunities, products and features while maximizing productivity and quality.

AIMS is growing in popularity, as it enables shops of all sizes plus huge production departments the flexibility to integrate machining, metrology, and materials handling into a unified ecosystem with full data capture and management capabilities.

https://machines.anca.com/Products/Integrated-Manufacturing/AIMS (includes a video demo)

ANCA's AIMS (ANCA Integrated Manufacturing System) is the smart manufacturing solution for cutting tool production, enabling manufacturers to connect, automate and create like never before. The modular system comprises hardware and software components for automated, closed-loop manufacturing. AIMS Server controls production processes and AutoComp, the intelligent compensation module maintains part quality automatically, while the new AIMS Connect function covers job management.