Articles Tagged with ''Klingelnberg''

Technology Advancements in EV Inspection

Electric Vehicles Provide New Challenges as well as Opportunities

Read More

Quality Assurance Stakeholders Meet at Control 2022

Gleason and Klingelnberg unveil new quality assurance technologies

Read More

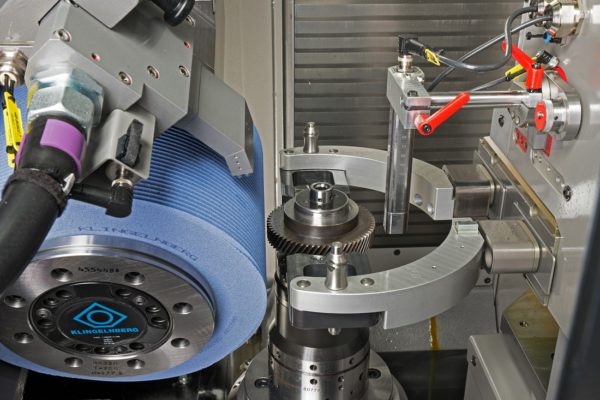

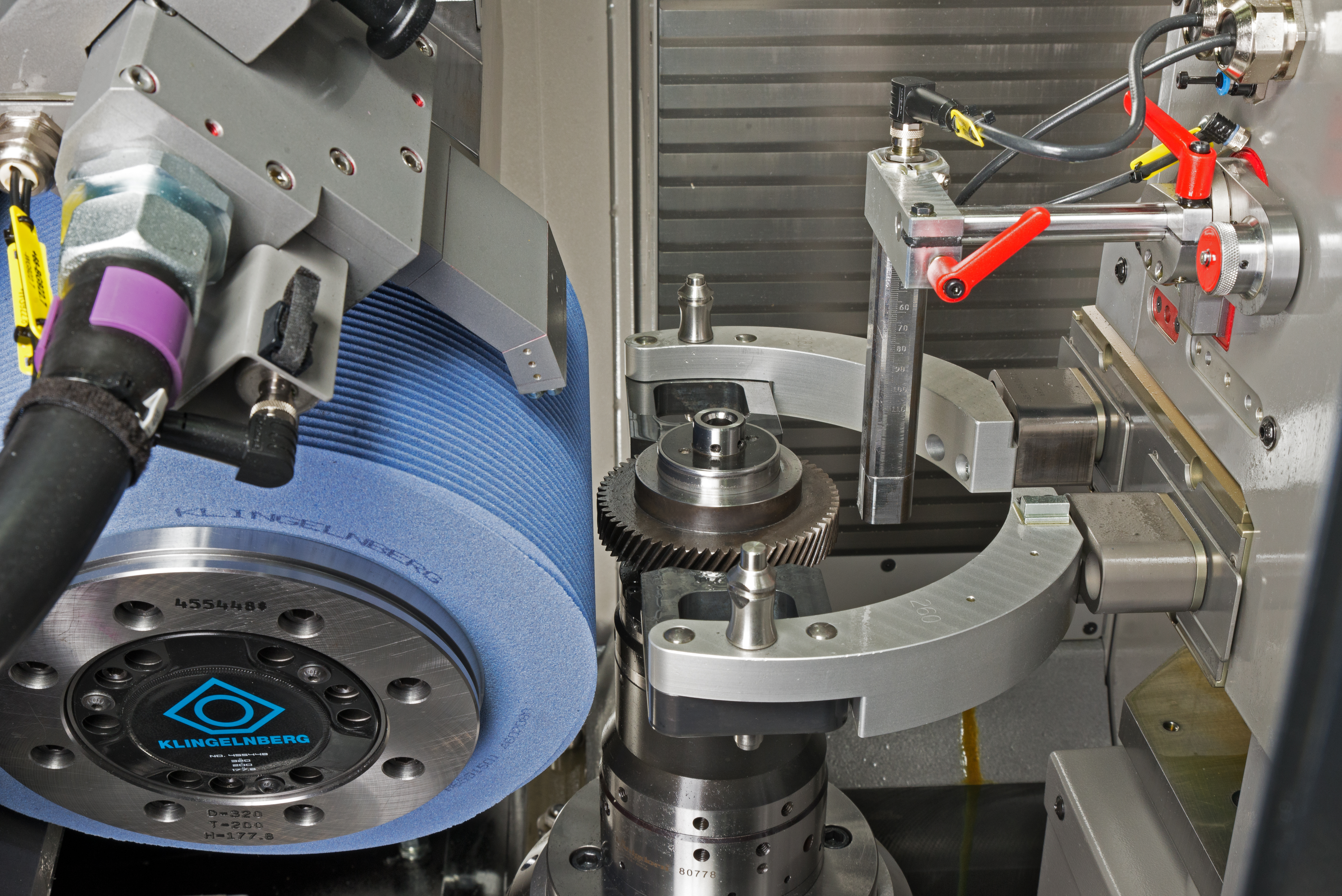

Process Variables for Gear Grinding

Tremec Offers Latest Transportation Technology with Assistance from Klingelnberg Speed Viper

Read More

A World of Smart Processing & Digital Advancements

What will gear manufacturing look like in the next five years?

Read More