Heat Treating

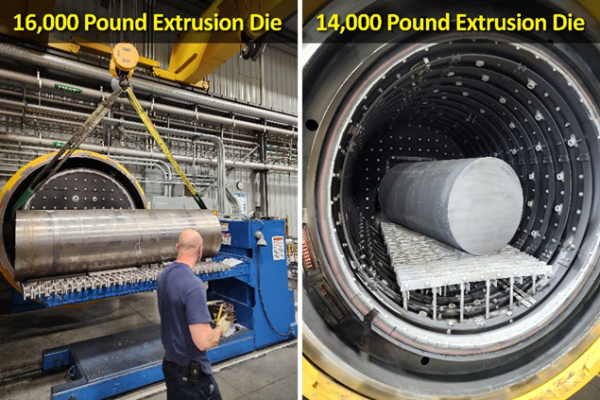

Take Control of Quenching

Press quenching technology for more hardening consistency, improved operator efficiency, and faster throughput of a wide range of gears and other close-tolerance cylindrical components

Read More

What’s Happening in Heat Treating?

Acquisitions, retirements and facility expansions highlight start to 2023

Read More