IMTS

Robotic machine tending, collaborative mobile robotics and other technologies for optimizing process efficiency and boosting productivity

Read More

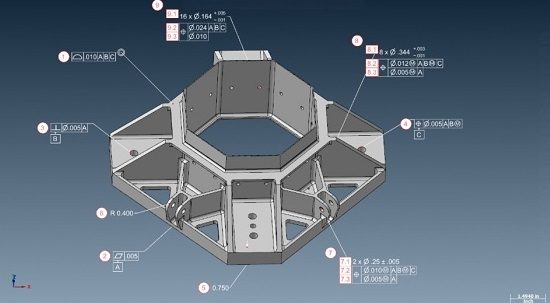

Innovative Workholding Solutions for Gearing Technology at IMTS 2022

Clamping systems save time and stabilize manufacturability

Read More

IMTS 2022 Booth Previews

The gear pavilion and beyond at McCormick Place, Chicago, September 11–17

Read More