Robotics

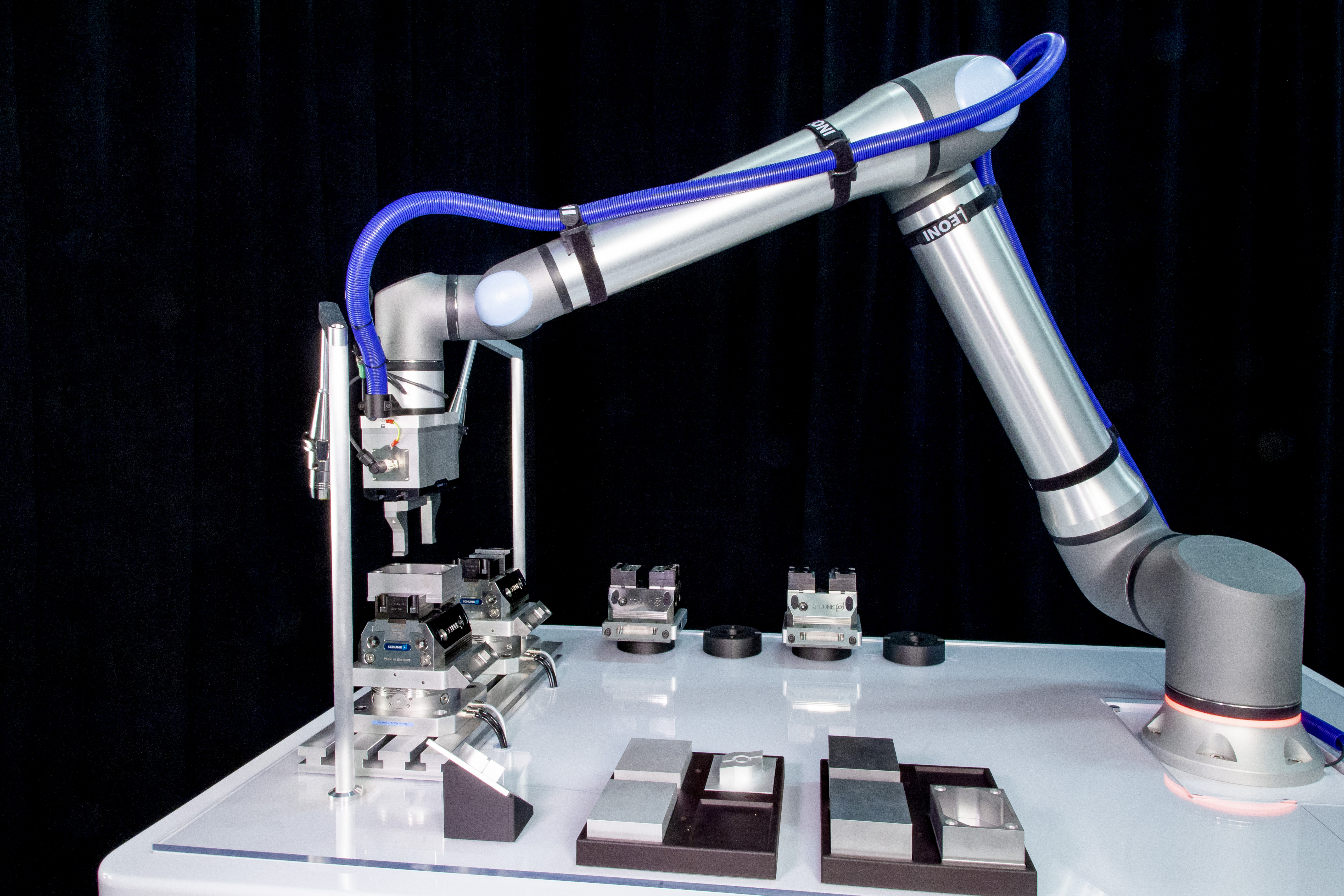

OnRobot Previews D:PLOY for Machine Tending at IMTS 2022

Powerful and Intuitive Automated Configuration Speeds Deployment of Robotic Machine Cells

Read More

Stäubli Robotics to Show New Manufacturing Technologies at IMTS 2022 in Chicago

Robotic machine tending, collaborative mobile robotics and other technologies for optimizing process efficiency and boosting productivity

Read More

Beaumont Machine Reacquired by Founders

Global EDM supplier also moves to new location to enhance production and service capabilities

Read More