Electrification

Transportation Alterations

NVH, energy efficiency, and lightweight vehicles drive Eaton’s EV culture

Read More

The Changing Face of Battery Manufacturing in North America

Automotive companies add “mining” to their growing field of interests in the age of e-mobility

Read More

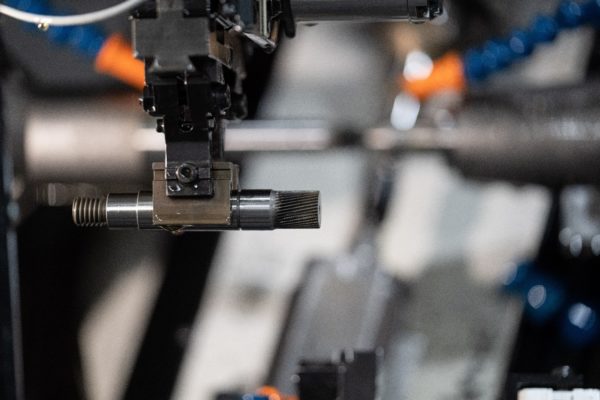

Efficient Turnkey Machining of Complex E-drive Components

Perfect E-Shaft with Integrated Production Solution

Read More

CTI USA Symposium 2023 Recap

Range anxiety, infrastructure debates, raw material shortages and unanswered questions shake up automotive’s move toward electrification—the journey won’t be easy, but the industry will push technology until it finds a way.

Read More