Features

Profile: Continuing Education and Training with the AGMA

Programs for professional development of the gear-manufacturing workforce

Read More

Reigniting the Educational Infrastructure

How data-driven education, virtual reality, and sociology can assist the skilled workers crisis

Read More

The Afterglow of Furnaces North America 2022

Takeaways from the heat-treating industry’s premier event

Read More

State of the Powder Metal Industry

MPIF Takes a Look at Market Disruptions and Future Forecasts

Read More

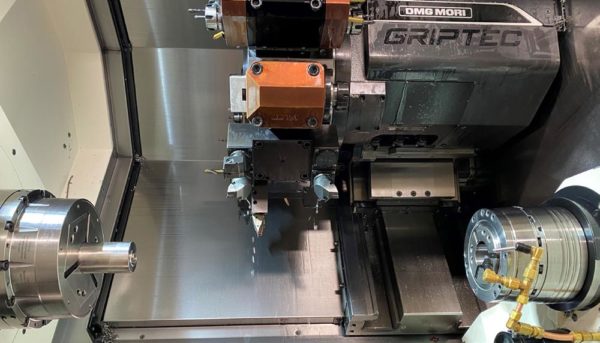

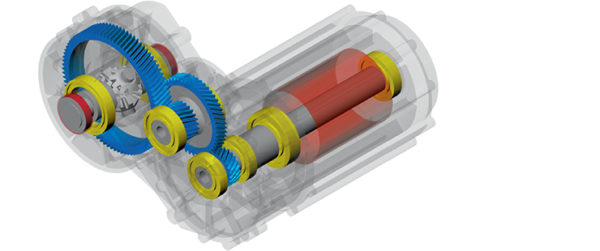

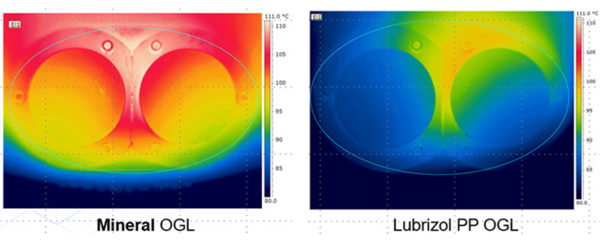

Precision Equals Performance at ZPE GripTec

Automotive racing components need rapid manufacturing capabilities to win the race

Read More