Articles by Matthew Jaster

How data-driven education, virtual reality, and sociology can assist the skilled workers crisis

Read More

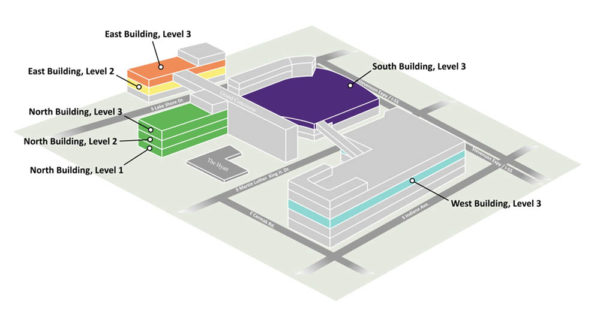

IMTS 2022 Booth Previews

The gear pavilion and beyond at McCormick Place, Chicago, September 11–17

Read More

Technology Advancements in EV Inspection

Electric Vehicles Provide New Challenges as well as Opportunities

Read More

Metal Cutting Robots

Kadia Offers Deburring Robot Cells for Gear and General Machining Requirements

Read More

Light, Movement, Perspective, LEGO!

Why Every Gear Geek Should Visit “The Art of the Brick”

Read More