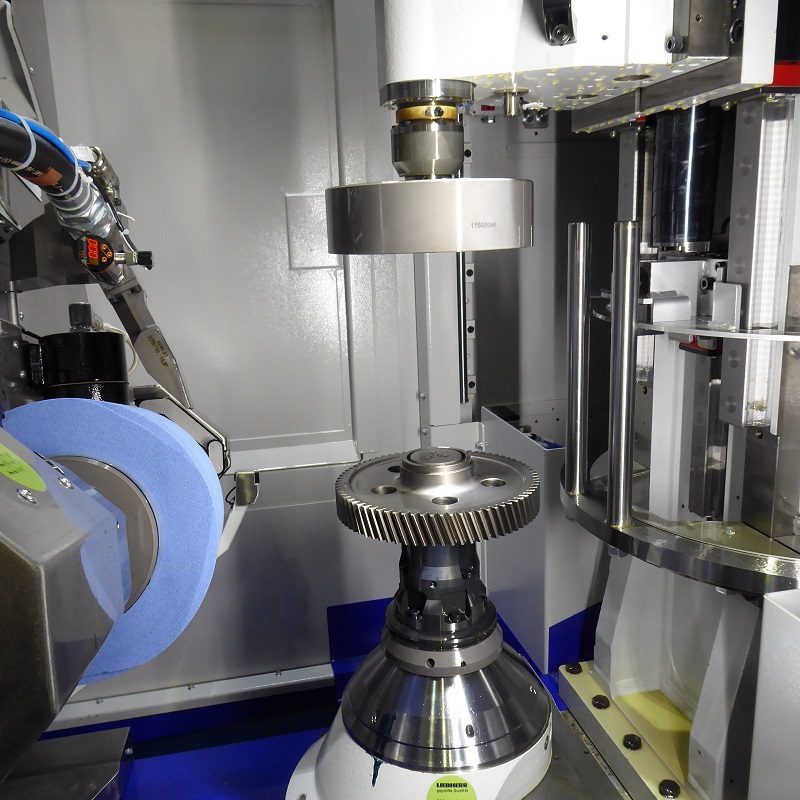

Liebherr provides clamping solution for diverse requirements

SECLA offers easy operation combined with maximum flexibility and short setup times. These are the clamping arbor features that Liebherr has been successfully using in its own gear cutting machines for many years. Anyone who buys a SECLA from Liebherr benefits from manufacturing to after-sales service, as the company offers everything from a single source.

Customer feedback was so positive that, in 2019, Liebherr decided to offer the clamping fixture as a separately available component. The clamping arbor manufactured by Liebherr offers modular construction, enabling a clamping fixture exchange in next to no time.

Short delivery times

As well as its diverse variety and its robustness, which make it suitable for different workpieces, the SECLA also impresses with its fast availability. A complete clamping device can be delivered within 10 weeks, while individual components such as the clamping arbor, clamping base and the mounting for the counter column are in stock and thus immediately available.

Liebherr even goes one step further and provides customers with the interface geometry of individual, workpiece-touching components – for example, the workpiece support, the centering tip or the clamping top – for their own production.

Work area and collision monitoring in advance

Liebherr offers a special peripheral service for the clamping fixture: in case of possible interfering contours, Liebherr conducts advance collision monitoring in the work area as an engineering service. This ensures that production can start immediately after installing the clamping device.

SECLA service help desk

Liebherr has set up a help desk for any questions concerning SECLA. The employees can be reached by telephone or email and will answer any questions about technology, delivery times or commercial handling, or will connect you with the right person.