Revolutions

Thermoplastic injection-molded parts in automotive applications is growing and proving significant reductions in NVH issues

Read More

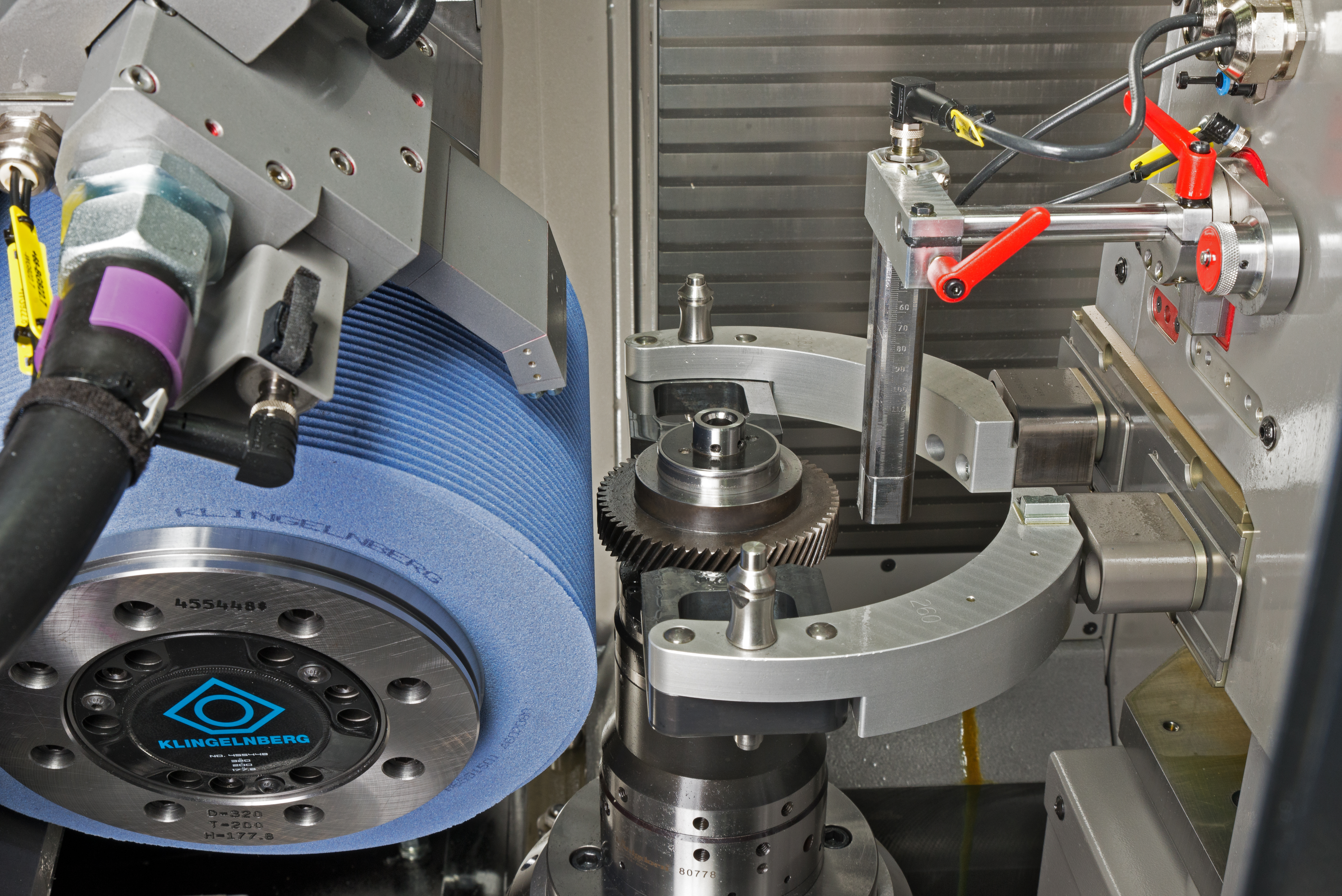

Process Variables for Gear Grinding

Tremec Offers Latest Transportation Technology with Assistance from Klingelnberg Speed Viper

Read More

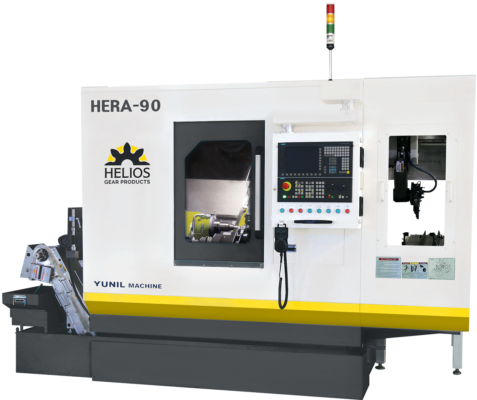

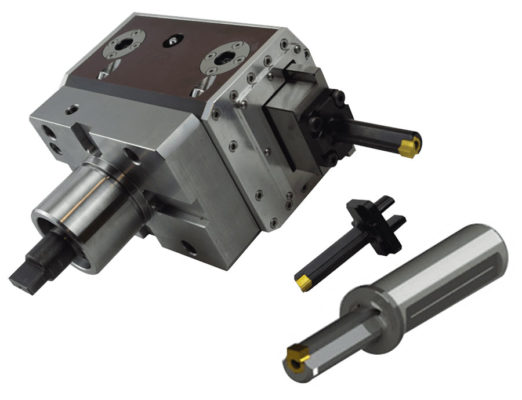

Versatile Hobbing Solutions from Affolter, Helios and Nidec

Improved productivity and reduced processing costs drive innovation

Read More

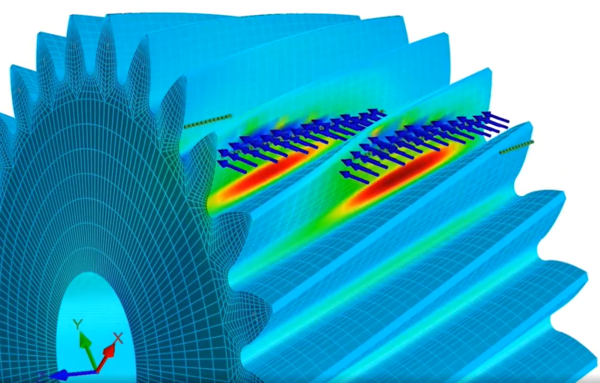

The Role of Virtual Prototyping in Gear System Design and Manufacturing for E-Mobility

The combination of full-system simulation and gear-machining simulation ensures manufacturability

Read More

The Evolution of QuesTek's Ferrium C64 for Additive Manufacturing

The unique processing conditions of 3D-printed metal gears have come a long way

Read More

Recent Comments

With a sliding gear system, after disengaging, there...

Hi there, Nice Blog. Thanks for sharing the blog...

Not too dissimilar to the sliding gear system...

Request for details of this new advance methods...