Items Tagged with 'Nidec Machine Tool Corporation'

ARTICLES

IMTS 2022 Booth Previews

The gear pavilion and beyond at McCormick Place, Chicago, September 11–17

Read More

Preview of 3D Printing at IMTS 2022

A sneak peek into the booths of JEOL USA, Nidec Machine Tool, and Fortify

Read More

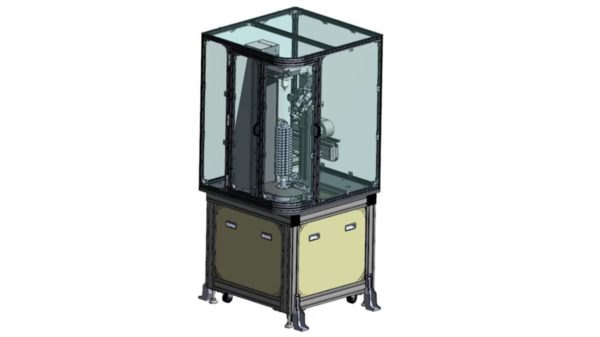

Nidec Machine Tool Develops Gear Shaping Machine for High-Precision Small-Module Gears Used in Robots

Simultaneously Developed Dedicated Cutting Tool Enables One-Stop Support in Gear Cutting Machines and Cutting Tools

Read More