Items Tagged with 'Nidec Machine Tool America'

ARTICLES

Step Right Up! It’s Time to Preview IMTS 2024

A practical guide to the latest from the manufacturing world

Read More

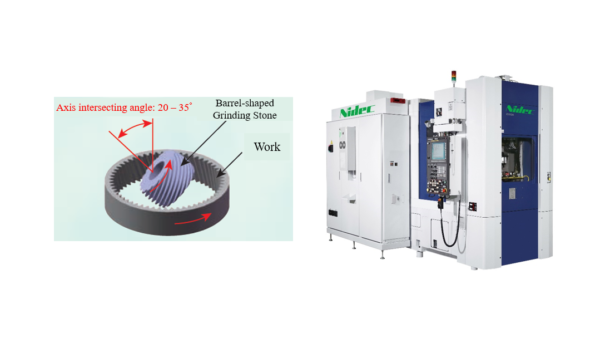

Wenzel and Nidec Machine Tool America Announce Open House

Gear Up For Precision event will be April 12–13, 2023, in Wixom, Mich.

Read More