EMAG Offers R 300 Hobbing Machine to HKS Dreh-Antriebe

Rotary actuators are jacks-of-all-trades: They are implemented whenever an object must be rotated or swiveled—this is necessary during the production of utility vehicles, ships, machines, power plants, and production areas. This broad range of uses defines the challenging tasks that HKS Dreh-Antriebe GmbH is facing, as it is the market-leading producer of this interesting technology. The company uses EMAG vertical hobbing machines to create special external gearings on the central piston of the rotary actuator: Two of these are installed at the HKS location in Hesse, Germany, and a new R 300 unit at the Neukirch plant in Saxony. These machines have a very demanding list of requirements that must be met. Due to the variety of products, the machine must be retooled frequently and still be able to deliver flawless gearing quality. Executives at HKS make an “all-round positive” assessment of their new investment decision.

Being able to accelerate, brake, precisely position and then hold an object in place is not an uncommon request. That’s why one would be tempted to ask: Where are rotary actuators not used? We frequently run into this technology in our day-to-day lives. For instance, when a garbage truck from the local disposal service lifts the container and empties it with a swiveling motion, more often than not a powerful HKS actuator is providing the lifting power. The same applies for the fire department’s rescue platforms or particularly large excavator shovels. At the other end of the spectrum, rotary actuators from HKS are used in industrial production, for example, to ensure precise tipping of collection bins, quick movement of mixing devices or easy completion of a tool changes on a machine. Rotary actuators are based on various actuator principles and feature different performance characteristics and sizes.

Given all this diversity, is there such a thing as a broad basis for success at HKS? “At the end of the day, for us it’s always a matter of developing very precise actuators, being able to durably withstand the highest loads and work efficiently,” explains Mario Vogt, head of operations at the HKS plant in Neukirch. “We therefore develop highly customized solutions for many customers and operate our three production sites in Germany with high vertical integration. Our vast experience flows into each development. This is the basis on which we have become one of the leading manufacturers in this field worldwide.”

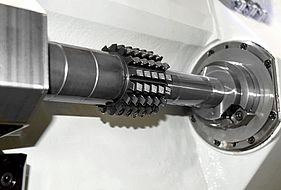

Another reason why this is such a particularly challenging type of gear production becomes obvious when looking at the various operating principles of rotary actuators. Take helical rotary actuators, for instance: This type of actuator converts the linear movement of an actuated piston into the required rotary motion. The piston’s high-helix thread is then combined with the internal gearing of a cylinder that surrounds it. The longer the linear movement of piston, the greater the rotational movement will be. The principle is as simple as it is effective. However, depending on the area of application, a tremendous amount of force may also be placed on these gearings. The typical areas of application for HKS torque motors in industry and engineering demand reliability. This is why only extremely stable and precise gearings are produced. Fault tolerance is “zero.” The fact that HKS executives approached EMAG with this challenge is no coincidence, since two EMAG hobbing machines are used at the production site in Wächtersbach, Hesse. Their reliability and efficiency should now make an impact at the Neukirch site, considering that the existing gear-cutting machines installed there were already aging.

“One of our goals was to handle growing production volumes for gears at a higher machining pace, since our technology is being implemented in a growing number of application areas,” explains Vogt. “At the same time, retooling the hobbing machine must be very fast and easy, since our batch sizes can range from one to 50. Batch size changes occur almost daily. That’s why it’s important for us that the retooling process can be completed within a few minutes, depending on the component. Production starts immediately once we’ve run in the machine with a sample.”

The R 300 vertical hobbing machine from EMAG has been running at HKS since March 2019. Throughout this time, there has been a tremendous increase in performance when compared to the previously used technology: the operation time has been drastically reduced from up to three hours to about 30 minutes, when machining very large gearings. At the same time, the tool life of the hob used has increased by approximately 30 percent. This means that tool costs are decreasing at HKS. To sum it up, the vertical hobbing machine is able to machine module 3 external gearings from 90 to 350 millimeters (4 – 14 in) in width. The pistons generally range from 200 to 500 millimeters (8 – 20 in) in length and weigh between 2 to 200 kilograms (4 – 441 lbs).

“This broad range of components is directly linked to a particular strength of EMAG's technology—exceptionally generous fundamental design principles,” explains Michael Ossot from EMAG sales. “We value the large machining area with long travel paths, as well as the wide range of speeds and performance capabilities, which allows us to machine components of all different sizes.”

The machine also stands out because of a variety of details in its design: the base of the machine is made of high-quality cast iron, which reduces vibrations. The machine is also very thermostable. The workpiece table with torque motor is another important aspect, since its direct drive is free of wear, backlash, and maintenance, and very precise in its movements. This benefits precision during the machining process. The double V guideways on all axes are another distinctive mark of quality.

In 2017, the EMAG Group acquired Richardon and gained their extensive experience in gear cutting for large components. It was important to HKS that this transition did not lead to any technological changes to the design of the machines, as confirmed by Vogt:

“We have had a great experience with this technology and obviously wanted to establish the same efficiency and flexibility at our Neukirch site—without any change in mechanical engineering. EMAG was able to guarantee this. We’re continuing to see the benefits of our investment decision. The machine allows us to produce significantly larger unit volumes in a comparable time period. Considering that rotary actuators are continuing to be implemented in a growing number of application areas and the market for this technology is growing, this is a key enabler of our success.”