Articles Tagged with ''software''

The goal is to optimize processes further and extend tool life to meet increasingly higher quality standards while reducing production costs

Read More

Delivering on the Promises of Digital Twins and Big Data

Balancing accuracy and precision in ISO 6336

Read More

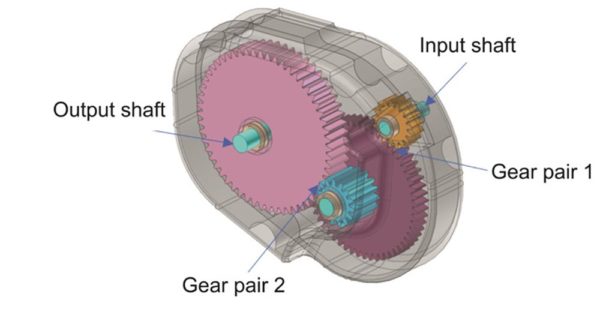

Maximizing Wind Turbine Gearbox Performance with Advanced Engineering Simulation

ZF Wind Power achieves wind turbine gearbox efficiency and reliability through Siemens Simcenter Solutions

Read More

Process Variables for Gear Grinding

Tremec Offers Latest Transportation Technology with Assistance from Klingelnberg Speed Viper

Read More