Industry 4.0

The benefits of lean manufacturing cannot be gained by just using tools primarily suited for an assembly factory

Read More

The Secrets to Implementing Lights-Out Machining

Making a whole day productive requires strategy not staffing

Read More

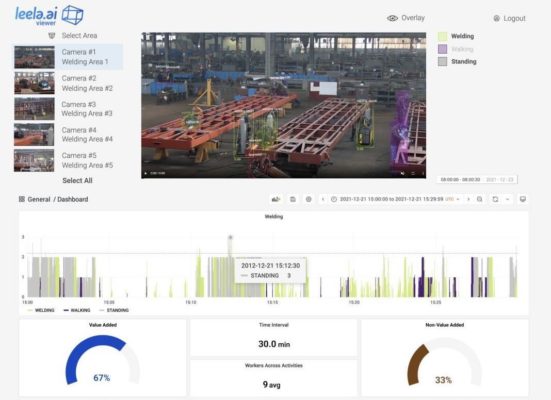

Leela AI Releases First Commonsense Visual AI Platform for Manufacturing

Product demonstration webinar scheduled for March 2, 12 p.m. EST

Read More

.jpg?height=400&t=1688057145&width=600)