State of the Gear Industry Perspectives takes an in-depth look at the challenges and opportunities in gear manufacturing today and in the future. Our fifth installment online is an interview with Adam Gimpert, president, Helios Gear Products.

Adam Gimpert

Adam Gimpert

What are the greatest challenges to your business in 2023?

Even though inflation cooled in the last two quarters of 2022, we continue to pivot to address employee wages/benefits and product pricing — while keeping our ears to the ground regarding market competition. No one has perfect foresight, but the situation does not seem to be fully settled, so our planning (financial, sales, marketing, operations) needs to incorporate an element of flexibility for 2023.

What global manufacturing trends are you paying close attention to in the gear industry today?

Smart manufacturing trends continue to be very interesting, and they have the chance to transform gear manufacturing. I feel this will be a “tipping point” change still years in the future, but I think it’s worth following as it evolves.

What is the state of your business regarding training and developing your skilled workforce internally and the state of finding skilled workers to join the organization?

Education is core to Helios’s mission, and I plan to focus even more time and energy on internal training. Maintaining existing strong personnel is key to successfully weathering any future industry disruptions, and I feel training must be part of the solution. Interestingly, online training resources continue to expand, so connecting the dots between these resources and employees who could benefit is the work to be done.

How is your organization evolving when it comes to emerging technologies such as IIoT, additive manufacturing, electrification, etc.?

More than ever, our teams are comfortable “working in the cloud,” but our communication and digital collaboration processes tend to mirror pre-cloud ways. This is a fundamental shift that we continue to address, and I expect to find more fluid and productive communication processes.

IIoT still suffers from heavy implementation costs and lack of industry standards, so only large manufacturers can carve out the resources to develop such solutions. These systems continue to be very specialized and implemented by third-party suppliers, so they will not hit the gear manufacturing industry at-large any time soon.

The EV industry is exciting because it has opened opportunities for start-up manufacturers and new players, which means potential new supply chains. Because some of this will be built from the ground up, there is opportunity to implement new collaboration technologies, such as digital twins, shared digital models, and digital-data-driven manufacturing processes.

What role is sustainability and green manufacturing playing in your organization in 2023?

Increasing energy costs are an obvious challenge to any business, so we have made simple improvements to our facility such as new LED lighting, presence sensors, and smart thermostats.

Describe the role automation/robotics plays in your business today and how these technologies will evolve in the coming years?

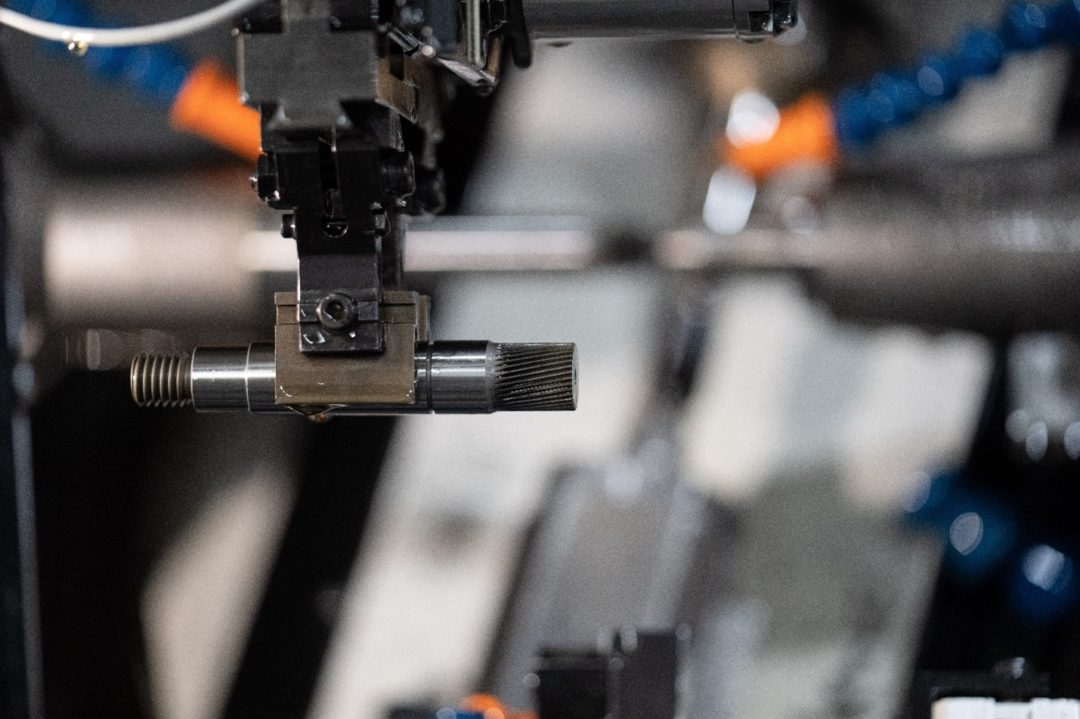

Our business has always focused heavily on automated gear manufacturing processes. Over the past 4 years, we have dramatically reduced the cost of these systems while keeping them simple and without a third-party integrator, which lowers the bar for manufacturers to benefit from them. Robots, cobots, new automation systems, and programming will also continue to evolve, meaning decreased costs and easier implementation. This will allow complete flexibility for manufacturers to easily re-tool cells and workflows to address changing market demands.

As gear shopfloors become more data-driven, how will hiring practices change in the gear industry moving forward? Do you believe it’s necessary to bring in system integrators, data engineers, and mechatronics experts to diversify your workforce?

Generally, yes, specialists will be needed to implement data-driven processes. For small- to medium-sized manufacturers, a diversified hire may be attractive — someone who can fill an implementer role but also a traditional manufacturing engineering function.

How will the gear industry change and evolve in the next five years?

Smart manufacturing will continue to trickle into the industry while automation remains a leading solution, albeit with more “intelligence” (IIoT) than in the past. 20th century manufacturers will slowly die away, and 21st century manufacturers (clean, digital, human-centric) will lead new business, acquisitions, and hiring.