Elastohydrodynamic Lubrication (EHL): A Review

Elastohydrodynamic Lubrication (EHL): A Review

Robert Errichello

Introduction

This review of elastohydrodynamic lubrication

(EHL) was derived from many

excellent sources (Refs. 1–5). The review

of Blok’s flash temperature theory was

derived from his publications (Refs. 6–9).

An excellent general reference on all

aspects of tribology is the Encyclopedia of

Tribology (Ref. 10).

Gear teeth, rolling element bearings, cams, and other non-conforming Hertzian contacts are lubricated by the EHL mechanism.

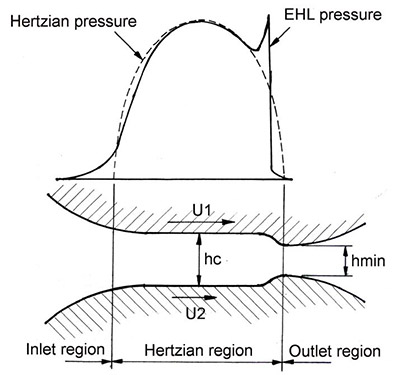

Figure 1 is an enlarged view of a lubricated Hertzian contact. It shows the distribution of film pressure and film thickness between two steel cylinders in rolling contact. Note that Figure 1 exaggerates the vertical distance and shrinks the horizontal distance for purposes of illustration. An actual EHL contact is typically 1,000 times wider than the film thickness. The EHL contact starts with a slowly converging inlet region where the lubricant is entrained and hydrodynamic pressure is generated. The film pressure gradually increases in the inlet region until it reaches the leading edge of the Hertzian region where the pressure quickly builds to values that are essentially equal to the Hertzian contact stress. Under high pressure, the lubricant viscosity increases exponentially to the extent that the lubricant cannot escape because its viscosity is too high. Within the Hertzian region, the bodies are separated by a constant film thickness. At the end of the Hertzian region there is a constriction near the outlet that forms the minimum film thickness. Within the Hertzian region the film pressure follows the Hertzian pressure, except for a sharp spike in pressure just upstream from the constriction at the outlet. Within the constriction, the film pressure drops rapidly to atmospheric pressure.

The inlet region. The lubricant that is adsorbed on the surfaces of the contacting bodies is entrained into the EHL contact by the rolling motion of the bodies. Entrainment of the lubricant is greatly facilitated by its viscosity increase because the high viscosity resists flow, makes it more difficult to squeeze the lubricant out, and viscous drag forces cause it to move with the surfaces into the Hertzian region. As a result, the inlet pumps the film up to a thickness that is sufficient to separate the opposing bodies.

EHL film thickness is determined by the viscosity and pressure-viscosity coefficient of the lubricant in the inlet region. For gears, the lubricant that is entrained into the inlet is molecularly attached to the surfaces of the pinion and wheel teeth and consists of thin boundary layers that immediately take on the bulk surface temperatures of the pinion and wheel teeth. Consequently, EHL film thickness is determined by the equilibrium bulk surface temperatures of the pinion and wheel teeth in the inlet region before the lubricant reaches the Hertzian region.

Bulk surface temperature. When the pinion and wheel are running under a given load, the surfaces of the pinion and wheel teeth are heated by the sliding friction between the gear teeth and gradually increase in temperature until finally reaching the equilibrium bulk surface temperatures after many revolutions.

Inlet shear heating. In a fully flooded EHL contact, only a fraction of the lubricant can pass through the contact. Therefore, some of the lubricant is rejected and reverse flow occurs in the inlet. Furthermore, if there is sliding in addition to rolling, heat is generated by shearing of the lubricant. Churning and shearing generate heat that increases the lubricant temperature above the average bulk surface temperatures. Therefore, the temperature that controls lubricant viscosity and EHL film thickness is the temperature of the lubricant in the inlet. Empirical equations are available to correct calculations of isothermal EHL film thickness to account for inlet shear heating.

Starvation. To form full EHL film thickness, the inlet region must be fully flooded. However, the inlet region might be starved of lubricant if the lubricant supply is inadequate, if very high speed causes fling off of the lubricant, or both. Under these conditions, EHL film thickness might be reduced. Empirical equations are available to correct calculations of isothermal EHL film thickness to account for lubricant starvation.

The Hertzian region. By the time the lubricant enters the Hertzian region, its viscosity has increased by a factor of 1,000 and it is trapped in the contact. At maximum Hertzian pressures typical in gears and rolling element bearings, the lubricant undergoes a phase transition into a solid glassy state. From this point on the lubricant no longer behaves as a Newtonian fluid, and it can be considered a pseudo-solid. In the Hertzian region the surfaces of the bodies are parallel and separated by the central film thickness that has an essentially constant thickness. The film within the Hertzian region is extremely stiff; therefore if the load increases, the bodies deform more than the central film thickness decreases. Consequently, EHL contacts are relatively insensitive to changes in load and the main effect of increasing load is to deform the surfaces, which increases the area of the Hertzian region, but does little to alter the shape of the inlet zone where the EHL film is formed. Bottom line, increasing load leaves the film thickness virtually unchanged.

Sliding within the Hertzian region. Sliding friction within the EHL film increases the bulk temperature of the gear teeth from a cold start by accumulating heat from each tooth engagement. The bulk temperature of the gear teeth increases until the heat input is equal to the heat loss to the surroundings. Once the bulk temperature reaches equilibrium, there is no further change in gear tooth bulk surface temperature — unless the operating conditions change. The heat input is confined to the immediate area of the Hertzian region and its duration is only a fraction of a millisecond long. Consequently, the heat produced by frictional heating within the EHL film is removed by conduction through the film into the tooth surfaces, and by convection as the hot oil exits the outlet region. Due to the short contact time the heat penetrates only a shallow distance into the gear teeth and is rapidly dissipated. Consequently, as the contact point moves on, the heat input disappears immediately and the surface temperature of the gear teeth returns promptly to the equilibrium bulk temperature. After one revolution of the gear, a particular point on the gear flank comes into engagement with essentially the same bulk temperature as the previous engagement. Although frictional heating does not directly alter the film thickness within the Hertzian region, any increase of the bulk surface temperatures due to frictional heating indirectly reduces film thickness by decreasing the viscosity of the lubricant in the inlet region.

The sliding is significant because it generates traction forces that result in energy losses. If the lubricant behaved like a Newtonian fluid, the high viscosity would lead to extremely high traction force. Fortunately, however, when subjected to high shear stresses the lubricant behaves like a plastic pseudo-solid with limited shear strength that is characterized by its traction coefficient. The bulk surface temperatures are controlled by heat generated in the Hertzian region and

the temperatures can vary significantly, depending on the molecular structure of the lubricant base stock, which influences a lubricant’s solidification pressure, shear strength, and traction coefficient. Furthermore, depending on anti-wear and anti-scuff additives that may be in the lubricant, the sliding and heat generate boundary tribofilms that help to prevent adhesive wear.

Shear thinning. Lubricants containing high molecular weight polymers, which are additives known as a viscosity index (VI) improvers, may lose viscosity under the high shear rates that occur in the Hertzian region and reduce the EHL film thickness. This is known as shear thinning.

The outlet region. As the lubricant leaves the Hertzian zone, film pressure tends to boost the lubricant flow toward the outlet region. The amount of lubricant within the contact is controlled by the inlet and continuity of flow can only be maintained if there is a local restriction in the outflow, which causes a constriction to form at the outlet. This is the position where the minimum film thickness occurs. A sharp spike is generated in the film pressure next to the constriction on the upstream side. The pressure drops abruptly to atmospheric pressure downstream of the spike and the lubricant viscosity returns to its atmospheric viscosity. Consequently, the contact pressure between the surfaces is negligible in the area of the minimum film thickness. The divergent region of the outlet generates negative pressure that causes dissolved gases in the lubricant to come out of solution. This ruptures the lubricant film, which cavitates and forms a wavy wake that consists of separate lubricant streamers intermixed with air.

Significance of the three regions.

The inlet region pumps the film up, the

Hertzian region rides the film, and the

outlet region discharges it. As the lubricant

passes through the three regions,

it viscosity increases exponentially, and

the lubricant changes phase from a freely

flowing fluid in the inlet region, to a

pseudo-solid within the Hertzian region,

and back to a freely flowing fluid in the

outlet region — all within a matter of milliseconds.

Lubricant emerging from the

wake of the outlet region is indistinguishable

from lubricant that entered the inlet

region. The film forming capability of the

zPinion number of teeth work gear inlet region is governed by the local viscosity

of the lubricant in the inlet, which

is controlled by the bulk temperatures

of the surfaces and inlet shear heating.

Consequently, the central film thickness

is established by the lubricant properties

in the inlet region. Once in the Hertzian

region, the lubricant acts as a pseudo-solid

where it influences the traction coefficient,

boundary tribofilms, and bulk surface

temperatures. Finally the outlet region

adjusts the minimum film thickness to

maintain continuity of lubricant flow.

Blok’s flash temperature theory. In 1937 Blok published his flash temperature theory in a series of papers (Refs. 6–8). Blok defined the contact temperature as the sum of the bulk surface temperatures of the gear teeth, and the flash temperature rise associated with frictional heating in regions of asperity contact. Blok in 1969 published the thermal- network method (Ref. 9) for calculating the equilibrium bulk temperatures of gear teeth. Blok’s theory of scuffing proposes that scuffing occurs when the maximum value of the contact temperature reaches a critical temperature. He predicted the surface temperature based on the following assumptions:

- The surfaces are in intimate contact or perfectly insulated

- All the heat is removed by one-dimensional conduction straight down into the surfaces

- The two bulk temperatures are identical

Assumption (1) is violated if an EHL film is present; assumption (2) is violated if the speed of either surface is too slow; and assumption (3) is violated for a high gear ratio because the pinion typically runs hotter than the wheel. Therefore, Blok’s flash temperature theory applies only to the boundary lubrication regime where the EHL film is non-existent, and the only protection against scuffing is any tribofilm deposited by lubricant additives. But once the tribofilms fail, the lone remaining protection is the natural oxide layer on the gear teeth. Consequently, Blok’s flash temperature is not applicable to the mixed-film or full EHL regime.

References

- Tallian, T.E. “Elastohydrodynamic Hertzian Contacts,” Mechanical Engineering, Part 1, 1971, Nov, pp 14–18, Part: 2, Dec, pp 17–22.

- Wedeven, L.D. “What is EHD?” ASLE Lubrication Engineering, 1975, 31, 6, pp. 291– 296.

- Mobil EHL Guidebook. “Elastohydrodynamic Lubrication (EHL),” 1992, pp 1–13.

- Olver, A.V. “Gear Lubrication: A Review,” J. Engr. Tribology, Proc. Inst. Mech. Engrs., 216, 2002, J, pp 255–267.

- Larsson, R. “EHL Film Thickness Behavior,” Encyclopedia of Tribology, Vol 2, 2013, pp 817– 827.

- Blok, H. “Les Temperatures de Surface Dans des Conditions de Graissage Sous Pression Conditions,” Proceedings of Second World Petroleum Congress (Paris), 4, 1937 a, pp 151– 182.

- Blok, H. (1937b) “Measurement of temperature flashes on gear teeth under extreme pressure conditions,” Inst. Mech. Engrs, Proceedings of the General Discussion on Lubrication and Lubricants, 2, 1937 b. pp 14–20.

- Blok, H. “Theoretical study of temperature rise at surfaces of actual contact under oiliness lubricating conditions,” Proceedings of the General Discussion on Lubrication and Lubricants, 2, 1937 c, pp 222–235.

- Blok, H. “The Thermal-Network Method for Predicting Bulk Temperatures in Gear Transmissions,” Proc. 7th Round-Table Discussion on Marine Reduction Gears, 1969, Stal-Laval, Finspong, Sweden, pp 3–25.

- Wang Q.P. and Y.W. Chung. (Eds.) Springer Reference, Encyclopedia of Tribology, Volumes 1–6.