Nidec Machine Tool Launches Robot Cameras for Hobbing and Broaching Machines to Help Automate Visual Inspections of Cutting Tools

Nidec Machine Tool Corporation announced today that it has launched Robot Camera SPEED, visual inspection equipment for cutting tools (hobbing machines) to process gears and other components, and Robot Camera MAX, visual inspection equipment for broaching machines. These Robot Cameras use a digital camera to automatically shoot images of cutting tools’ edges at a high speed and with high accuracy, and save the graphic data of those images. By entering a tool’s specifications into a Robot Camera, the user can have it determine what images to shoot of tools of different shapes, and identify any missing part on the edge of a cutting edge and any detached portion of coating, while judging if any problem exists with a tool’s visual appearance, including its wear status. The Robot Cameras were both developed for the automation of Nidec’s cutting tool manufacturing and regrinding. This improves their quality and can reduce inspection time by 90%.

Robot Camera SPEED, Nidec’s latest inspection equipment for hobbing machines, can capture images of hob cutters with a straight or spiral tooth depth with an external diameter of 20 - 130mm, a total length of 50 - 350mm, and a weight of up to 20kg. With the images of all blades taken from four different directions with high accuracy, Robot Camera SPEED can determine if there is any problem with the cutting tool. Robot Camera MAX can accommodate a large and long tool with a maximum diameter of 200mm, a length of 2,300mm, and a weight of 30kg. It can capture images of any blade alignment, such as straight, helical, and spline.

Both “SPEED” and “MAX” are now available as part of Nidec Machine Tool’s strategy to improve its cutting tool-related services. Nidec Machine Tool is committed to actively working to solve its customer’s problems.

Hob Inspection Equipment Robot Camera SPEED

Hob Inspection Equipment Robot Camera SPEED

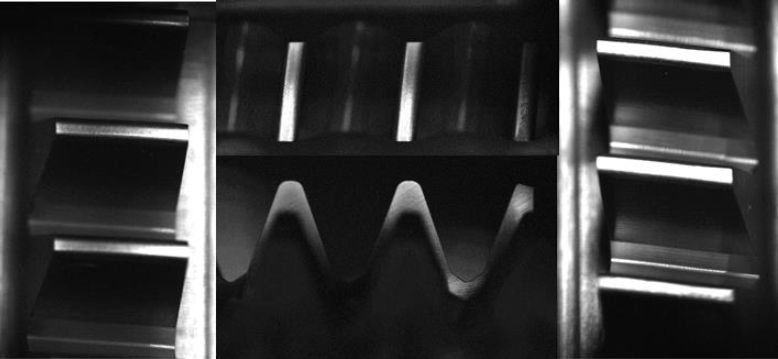

Sample images shot by Robot Camera SPEED

Sample images shot by Robot Camera SPEED

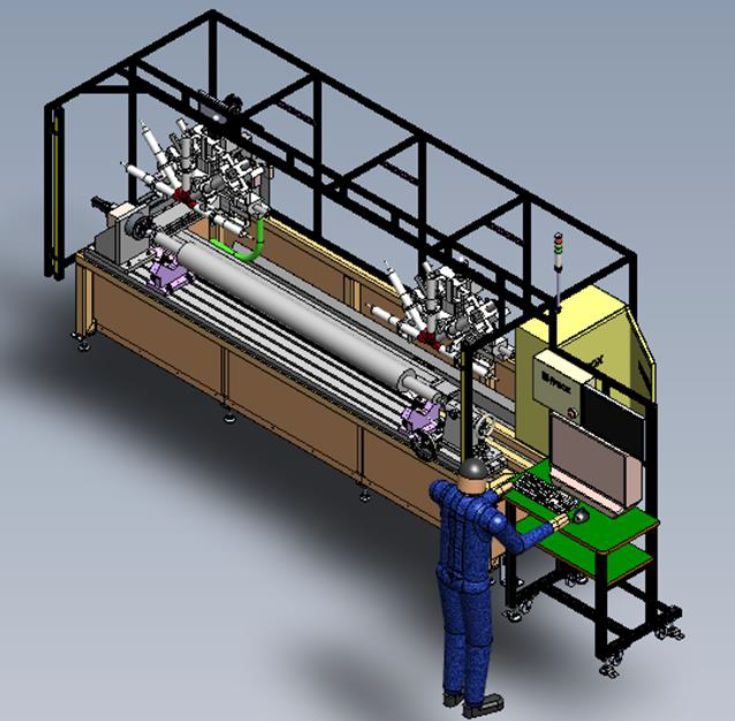

Broach Inspection Equipment Robot Camera MAX

Broach Inspection Equipment Robot Camera MAX

Sample images shot by Robot Camera MAX

Sample images shot by Robot Camera MAX