Articles Tagged with ''Gleason Corporation''

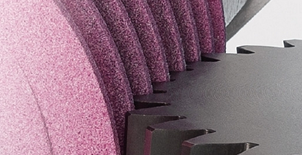

Quality Assurance Stakeholders Meet at Control 2022

Gleason and Klingelnberg unveil new quality assurance technologies

Read More

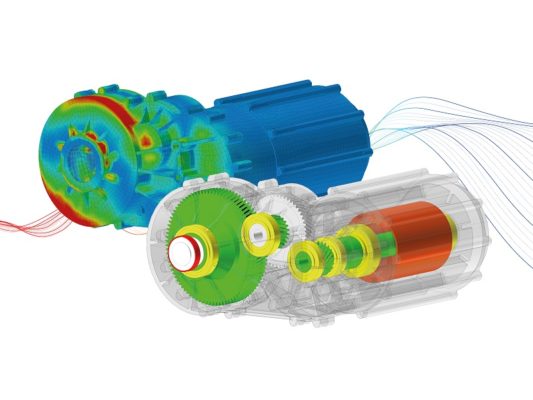

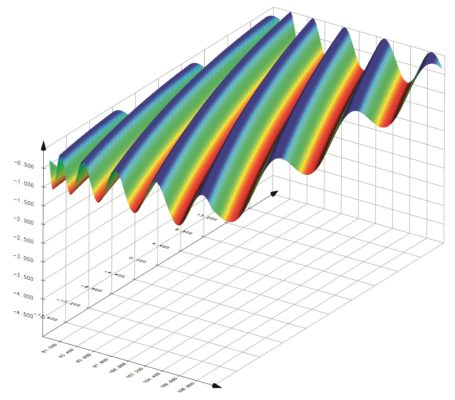

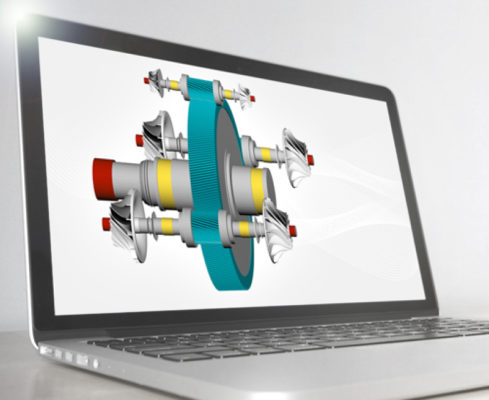

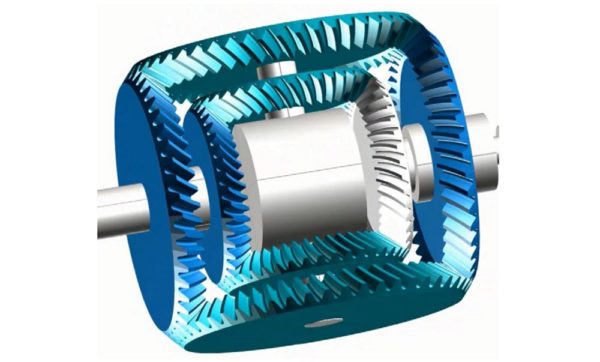

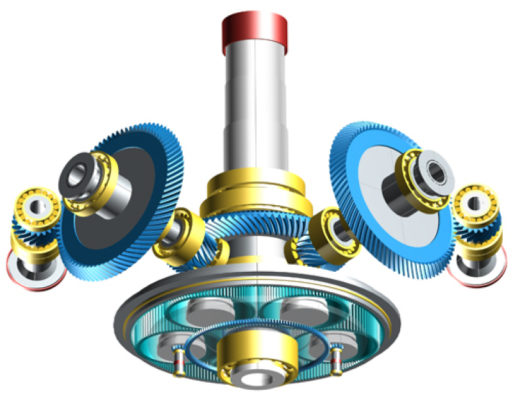

KISSsoft for Gear Manufacturing

Software integrates design, production, and metrology as a holistic process

Read More