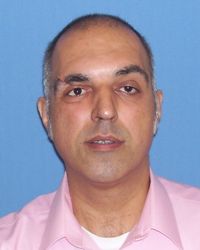

Haris Ligata works as the Manager of Bevel Gear Technology in Gleason's R&D Department (Rochester, NY). He joined Gleason in 2017 as a Senior Gear Theoretician, working on the cutting blade inspection and bevel gear technology. Prior to Gleason, he worked in GE's Global Research Center (Schenectady, NY) on a wide range of projects related to the rotating machinery, and in American Axle & Manufacturing (Detroit, MI) on straight bevel and helical gear differential technology. He obtained his Ph.D. degree in Mechanical Engineering from the Gear Lab at The Ohio State University in 2007.

The fascination of the automotive differential has led to the idea to build a second differential unit around a first center unit. Both units have the same axes around which they rotate with different speeds. The potential of double differentials as ultrahigh reduction speed reducers is significant. Only the tooth-count of the gears in the outer differential unit must be changed in order to achieve ratios between 5 and 80 without a noticeable change of the transmission size.