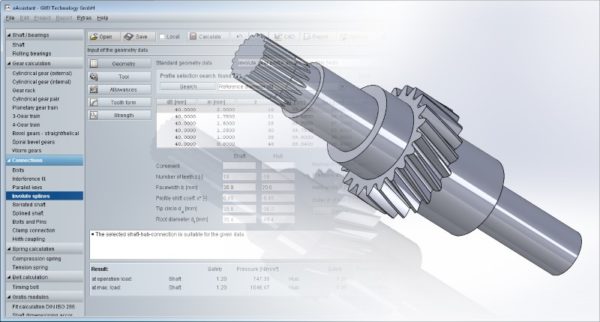

Software

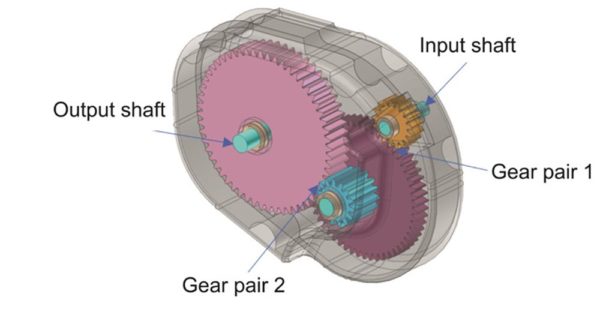

The “Differential Difference” in E-Drives

Forged differential gears don’t deliver the stronger, quieter performance required by e-drives—for that, there’s Coniflex Pro

Read More

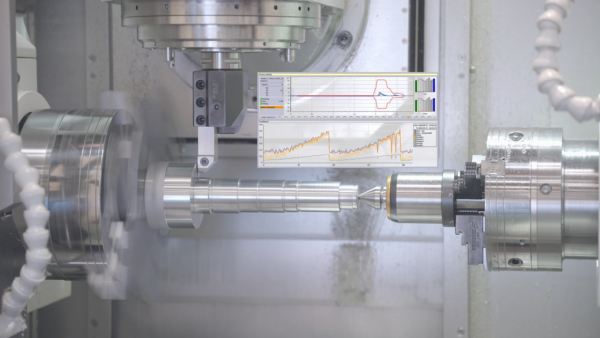

Hot Technologies to Help Cool the Planet

With global wind turbine demand set to quadruple by the end of the decade, manufacturers are seeking new technologies to ramp up production of gears that can operate in any environment, around the clock, for years to come.

Read More