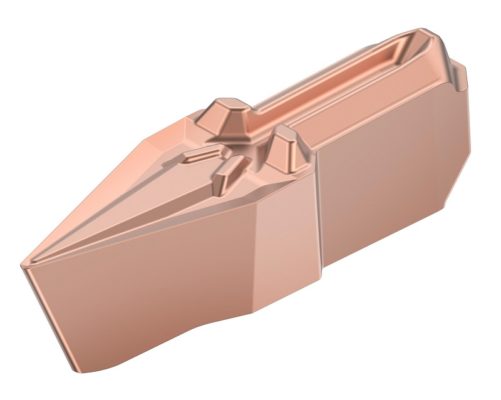

Cutting Tools

Sandvik Coromant Holds Automotive Transmission Machining Event at New Training Center

Topics included breakthrough methods for turning and skiving and tips to decrease cost per part, reduce setup and increase precision

Read More