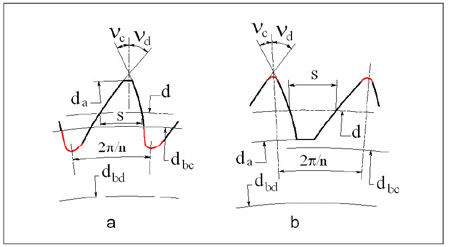

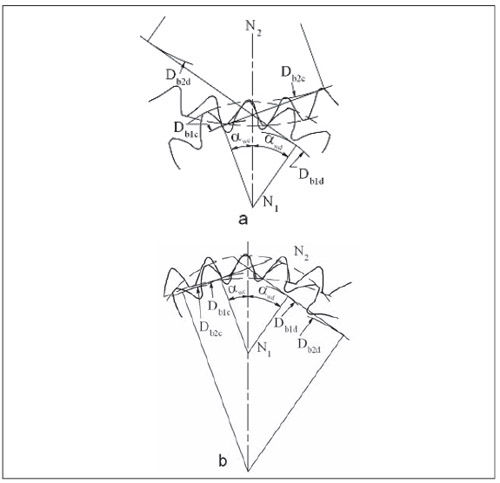

In propulsion gear transmissions, the tooth load on one flank is significantly higher and is applied for longer periods of time than the opposite one. An asymmetric tooth shape reflects this functional difference. Design intent of asymmetric gear teeth is to improve performance of the primary drive profiles by some degrading performance of the opposite coast profiles. The coast profiles are unloaded or lightly loaded during a relatively short work period. Asymmetric tooth profiles also make it possible to simultaneously increase the contact ratio and operating pressure angle beyond the conventional gears’ limits. In planetary gear systems, the planet gear is usually in simultaneous contact with the sun and ring gears. The tooth load and number of the load cycles are equal for both flanks of the ring gear. However, one flank of the planet gear is in mesh with the concave tooth flank of the ring gear with internal teeth. The resulting contact stress in this mesh is much lower in comparison with contact stress of the convex tooth flanks in sun-planet gear contact, which defines the load capacity and size of the gears. In order to reduce this contact stress, the higher operating pressure angle was

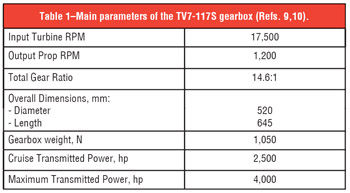

chosen for the sun-planet gear contacting tooth flanks. This choice is in compliance with the ANSI/AGMA 6123-B06 standard "Design Manual for Enclosed Epicyclic Gear Drives," which states: "Best strength-to-weight ratio is achieved with high operating pressure angles at the sun-to-planet mesh, and low operating pressure angles at the planet-to-ring gear mesh."

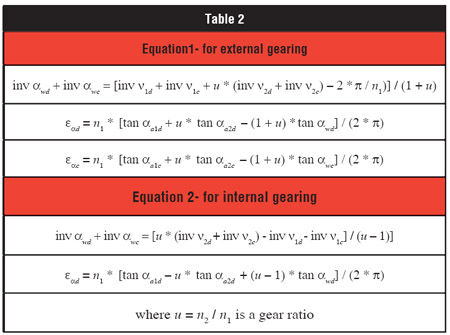

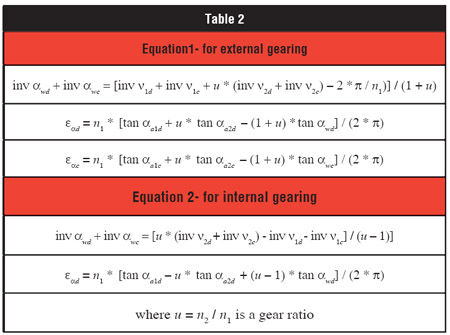

The drive tooth flanks of the sun-planet gear mesh have increased the contact curvature radii, resulting in greater hydrodynamic oil film thickness. This also reduces contact stresses, because the increased relative curvature increases the tooth contact area. Basic gear geometry parameters are presented in Table 3.

Direct Gear Design of the asymmetric tooth profiles also allows shaping the coast flanks and fillet independently from the drive flanks, reducing tooth stiffness and improving load sharing while keeping a desirable pressure angle and contact ratio on the drive profiles. This allows both increasing tooth tip deflection and damping tooth mesh impact, leading to gear noise and vibration reduction.

αwd 2-3 = arccos [cos (αwc 1-2) * (n3-n2) / (n1 + n2)] (3)

Where

αwc 1-2 - coast operating pressure angle in the sun-planet gear mesh;

n1 - sun gear number of teeth;

n2 - planet gear number of teeth;

n3 - ring gear number of teeth.

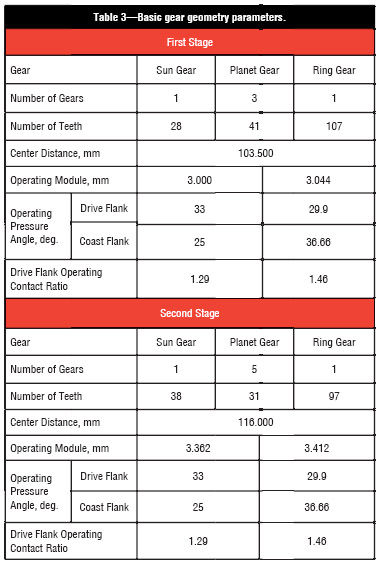

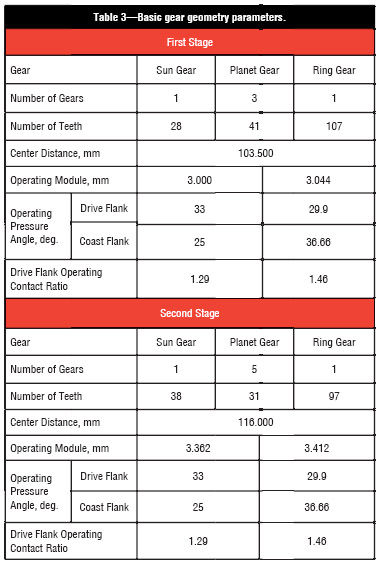

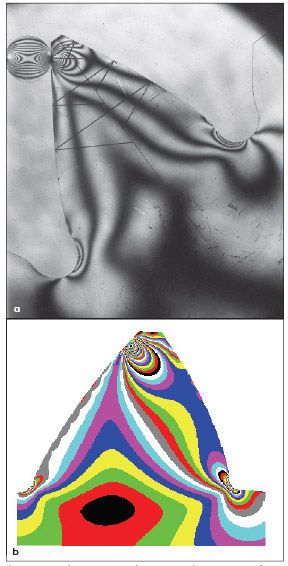

The geometry of asymmetric teeth does not allow using the traditional Lewis equation to define the tooth bending stress. Initially the photoelastic models (Fig. 5a) were used for the bending stress definition. Later FEA (Fig. 5b) allowed evaluating stress level more efficiently.

Figure 5--Asymmetric tooth; a-photoelastic model, b-stress isograms as a result of FEA.

Gear Manufacturing and Assembly

All gears are made from forged blanks of the steel 20KH3MVF (EI-415). Its chemical composition includes: Fe - base material, C (0.15-0.20%), S (<0.025%), P (<0.030%), Si (0.17-0.37%), Mn (0.25-0.50%), Cr (2.8-3.3%), Mo (0.35-0.55%), W (0.30-0.50%), Co (0.60-0.85%), and Ni (< 0.5%).

Machining of the directly designed sun and planet gears with asymmetric teeth requires custom gear hobs. The hob rack profile is defined by reverse generation of the gear profile. It is similar to the gear rack profile generated by a shaper cutter when this cutter is replaced by the asymmetric gear profile. Custom shaper cutters are used to machine the ring gear with internal teeth. Their profiles are also defined by reverse generation based on the ring gear geometry. The gear blank position during machining must provide the asymmetric teeth pointed in either the clockwise or counterclockwise direction. Otherwise, the drive flank of one gear will be positioned in contact with the coast profile of the mating gear, and assembly would be impossible.

After tooth cutting, the gears are carburized and heat-treated to achieve tooth surface hardness > 59 HRC with the case depth of 0.6-1.0 mm. The core tooth hardness is 33-45 HRC. Final gear machining includes tooth grinding and honing. Asymmetric gear flanks require special setup for both these operations.

Assembly of the gearbox includes selection of planet gears and their initial orientation, which is based on the transmission error function of every gear. All planet gears are classified by the transmission error (TE) function in several groups. Each group has planet gears with similar TE function. Position and orientation of each planet gear are assembled depending on its TE function profile, providing better engagement of the driving flanks and load distribution between planet gears (Ref. 12).

The TV7-117S turboprop engine gearbox components and assemblies are presented in Figs. 6-10.

Figure 6--First-stage sun gear assembly.

Figure 7--First-stage carrier and ring gear assembly.

Figure 8--Second-stage sun gear.

Figure 9--Second-stage carrier assembly.

Figure 10--Gearbox assembly.

Summary

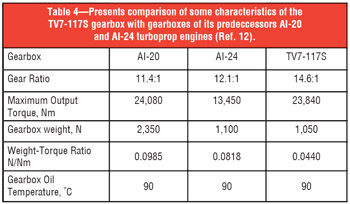

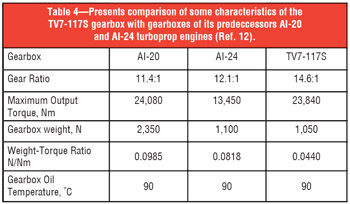

Application of the asymmetric teeth helped to provide extremely low weight-to-output torque ratio, significantly reduced noise and vibration levels--with less duration--and lower expense of operational development. Table 4 presents comparison of some characteristics of the TV7-117S gearbox with the gearboxes of its predecessors AI-20 and AI-24 turboprop engines (Ref. 12).

The new design and technological approaches that have found their realization in the TV7-117S engine gearbox were recommended for development of the gearboxes for advanced aviation engines.

References:

1. Vulgakov, E. B. "Gears with Improved Characteristics," Mashinostroenie, 1974 (in Russian).

2. Kapelevich, A. L. "Research and Development of Geometry of Modernized Involute Gears," Ph.D. Thesis, Moscow Bauman State Technical University, Moscow, Russia, 1984.

3. Kapelevich, A. L. "Synthesis of Asymmetric Involute Gearing," Mashinostroenie No. 1, pp. 62-67. Translated to English in Soviet Machine Science, Allerton Press, Inc., 1987, No 1, pp. 55-59.

4. Yoerkie, C.A. and A.G. Chory. "Acoustic Vibration Characteristics of High Contact Ratio Planetary Gears," The Journal of American Helicopter Society, Vol. 40, 1984, pp. 19-32.

5. Bolotovsky, I.A., O.F. Vasil'eva and V.P. Kotelnikov. "Involute Gears with Asymmetric Teeth," Vestnik Mashinostroeniya, Issue 4, 1984, pp. 15-17.

6. DiFrancesco, G. and S. Marini. "Structural Analysis of Asymmetrical Teeth: Reduction of Size and Weight," Gear Technology, September/October 1997, pp. 47-51.

7. Gang, G. and T. Nakanishi. "Enhancement of Bending Load Carrying Capacity of Gears Using an Asymmetric Involute Tooth," The JSME International Conference on Motion and Transmissions (MPT2001-Fukuoka), Fukuoka, JAPAN, 2001, pp. 513-517.

8. Karpat, F., K. Cavdar and F.C. Babalik. "Computer-aided Analysis of Involute Spur Gears with Asymmetric Teeth," VDI Berichte, 1904 I, 2005, pp. 145-163.

9. Vulgakov, E.B. and A.A. Sarkisov. "The New Gearbox of Klimov Corporation," Aerospace Courier, Issue 2, 2000, pp. 32-33.

10. Vulgakov, E.B. and A.L. Kapelevich. "The Gearbox for the TV7-117S Turbo-prop Engine," Vestnik Mashinostroeniya, 2000, Issue 11, pp. 13-17.

11. Kapelevich, A.L. "Geometry and Design of Involute Spur Gears with Asymmetric Teeth," Mechanism and Machine Theory, 2000, Issue 35, pp. 117-130.

12. Vulgakov, E.B., et al. Aviation Gearboxes, Handbook, Mashinostroenie, Moscow, 1981.

Dr. Vyacheslav M. Ananiev is a lead scientific researcher of the Central Institute of Aviation Motors (CIAM), Moscow, Russia. CIAM is a specialized Russian research and engineering facility dealing with advanced aerospace propulsion research, aircraft engine certification and gas dynamics-related issues. Dr. Ananiev is a prominent gear expert in the Russian aerospace industry.

Dr. Vladislav L. Dorofeyev is a lead designer of the gear transmissions department of the Federal State Unitary Enterprise at the Moscow Machine Building Production Plant "Salut." "Salut" is a specialized enterprise for the production and maintenance of engines for Russian military and commercial aircrafts. Dr. Dorofeyev is also a professor at the Moscow State Aviation Technological University named after K.E. Tsiolkovsky.

Dr. Alexander L. Kapelevich is president of the gear design consulting firm AKGears, LLC, located in Shoreview, Minnesota, USA. Working in the CIAM in the 1980s, he optimized the asymmetric tooth geometry for the TV7-117 engine gearbox. He is also a developer of the Direct Gear Design method. Dr. Kapelevich is an active member of the AGMA aerospace and plastic gearing committees.

Dr. Alexander S. Novikov is general director of the Moscow Machine-Building Plant named after V.V. Chernyshev, Moscow, Russia. The Moscow Machine-Building Plant manufactures and overhauls a number of aero engines for military and commercial aircrafts, including the TV7-117S turboprop engine. Mr. Novikov executes the general management of the company.

Dr. Alexander G. Paikin is a general engineer of the Moscow Machine-Building Plant named after V.V. Chernyshev, Moscow, Russia. Mr. Paikin executes the technical management of the company.