“Romax tends to perform one major release per year with additional interim updates,” says Andy Poon, director of software & strategy at Romax. “We believe incremental updates enable our customers to have access to new features as soon as possible rather than waiting for major releases in order to benefit from improvements to the software.”

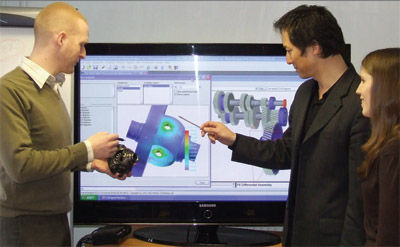

The software development team at Romax has grown enormously over the last 10 years. Poon says the most significant changes have occurred with its internal development processes and the way the company interfaces with its customers.

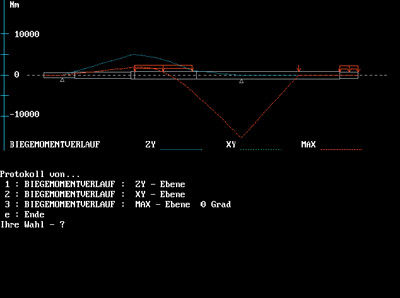

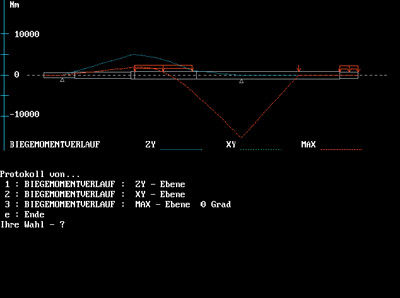

KISSsoft shaft calculation 20 years ago.

“In the very beginning, we pored over classical reference papers, documents from the standards committees, published technical papers and other technical documentation to figure out the requirements and how to program the algorithms,” Poon says. “Today, we work very closely with our customers on joint software developments and spend an increasing amount of time on research and development projects and university-based research programs.”

The Growing Needs of the Customer. The satisfaction of a job well done comes when the developers see customers solving real-world problems with their software. Poon says engineers at Romax believe the software is built with their customers in mind, noting its ready-to-use features and accessibility as being vital to the market.

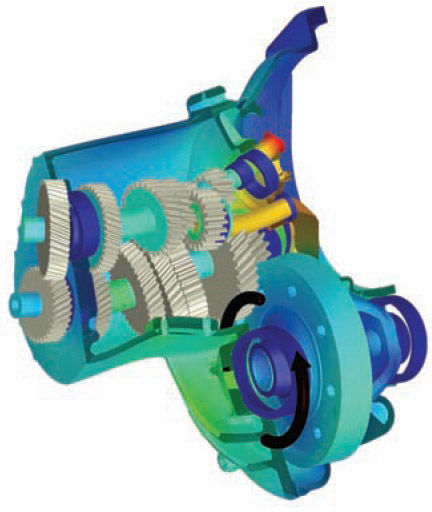

“Though we had access to a number of similar software packages, we continued using Romax for its ease of use and accuracy,” says Jon Adler, engineer at McLaren Performance Technologies, Inc. “Romax gives us a quick and complete way to evaluate the effects of design parameters on components within a gearbox. By evaluating loads in three dimensions, we can avoid over- or under-designing bearings and shafts.”

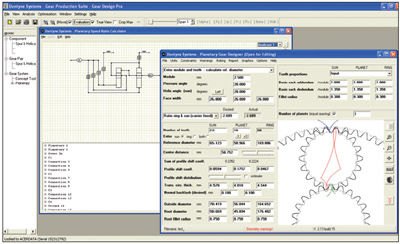

Fish explains the relationship with Dontyne’s customers is vital to enhance the “off-the-shelf” product. “In order to do justice to our products, we work closely with our customers to ensure that the software is properly implemented,” Fish says. “This has a dual benefit in that it allows the customer to become quickly adept, and allows us to realize where future product development will be most effective.”

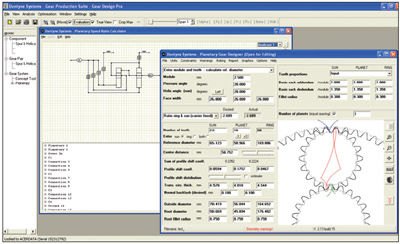

Image concept and planetary design tools by Dontyne Systems.

With relatively few software developers in the gear industry, companies are forced to maintain a strong customer base globally. Dontyne, Romax and KISSsoft maintain offices around the world to keep up with customer demands. Although KISSsoft is headquartered in Switzerland, the company works regularly with clients such as Brad Foote Gear Works in Illinois. (Now Tower Tech Holdings)

“Our interaction with KISSsoft has been excellent,” says Chuck Schultz, vice president of engineering at Brad Foote Gear. “My senior engineer went to a training session and came back fully confident he could use the software efficiently. When questions have come up concerning the software, our local rep has been able to get the answers within a day or so; as fast as you’d expect given the time difference. We went with KISSsoft originally on the recommendation of our own customers,” Schultz says.

Beermann says language barriers pose additional challenges when servicing a global community.

“Our software is currently available in five languages,” Beermann says. “We not only have to build a system and manage it, we have to know the technical terms of each language. We have an employee on staff strictly for language. It’s not just translating, it’s localization. It’s separating each technical term. Challenging work, but well worth it to get the product out to our global customers.”

Success in this industry, however, is achieved first and foremost in one’s own backyard. Fish says companies need to improve their own products with good housekeeping and effective data transfer between departments.

“Many companies have developed in-house calculation procedures based around international standards suited to their own manufacturing capability,” Fish says. “A major consequence of leaving this to a single person in the company is not often felt until that person leaves or retires.”

Is There a Qualified Engineer in the House? Effective software tools begin and end with a well-trained engineer. Beermann is concerned the most educated crop of experts might be on their way out. The company is preparing itself for a significant decline in gear industry expertise. He believes the typical “hardcore” gear expert in the U.S. is close to retirement.

“Our tools do not replace an engineer,” Beermann says. “You need someone in place with some know-how concerning the implemented methods.” (Editor’s Note: Please see our feature on engineering tuition/education on page 25 for additional information.)

Fish says there’s currently a major move to re-train engineers in the industry. The focus will be to ensure that any knowledge contained in software can be formatted and applied by engineers.

“Much of what was learned by sound and analytical techniques in the 60s and 70s has had to be relearned by a generation of engineers implementing a software routine.”

Dontyne has been working within the industry to help define the design procedures as well as the interpretation of equations and graphs in common standards. Along with a group that includes the ISO, BGA and AGMA, they’re currently looking at the influence of these decision-applying standards. Romax has also been involved in these discussions.

With the limited pool of experts in the field, it’s no surprise how important collaboration is to the success of software development in the gear industry.

Beermann believes most gear conferences often have the air of a family gathering.

“In my experience, most of the gear engineers are open to exchanging know-how and ideas with each other. The same is valid for companies providing gear design software.”

While the designers tend to split between independent software vendors (ISVs) and academic institutes, Poon doesn’t think there are any hard and fast rules to collaboration.

“Some ISVs are quite secretive. Likewise, the academic institutes or consortiums have to serve their members, although they do collaborate with industry partners. However, even the academics do specific work which is often subject to non-disclosure agreements.”

Dontyne’s GATES software was developed in collaboration with the Design Unit at Newcastle University, U.K.

“Our industrial development partners and beta testers test the analysis tools before they are released and form an important bridge from theoretical analysis to the engineering tool,” Fish says. “The most rewarding part of the job is seeing the change in attitude when a company realizes the benefits of our products to their operation. We’re delighted to promote our collaboration as much as possible. It publicizes the fact our capabilities extend beyond the software itself.”

Moving Forward. For Dontyne, gear software development in the coming years rests on bridging the gaps that sometimes exist between design, machining and inspection.

“Digital data from CNC equipment can be directly accessed to enhance the models. Machines can have value-added by incorporating further analysis features. A machine tool with on-board correction capability can also have on-board modeling of the component. Advanced modeling ensures that variables in the production processes can be calculated and analyzed, and the corrective action defined before the machining process even begins.

KISSsoft AG has also been adapting to the learning curves associated with software development. “CAD programs change, hardware platforms change, operating systems change and gearing standards are under continuous modifications,” Beermann says. “These are not problems, but a necessary part of our customer service to keep our software ahead of the industry. Due to the higher performance of computers, we can now implement features today that would have been out of discussion 20 years ago.”

Emerging manufacturing markets in China, India and Korea appear to be the focus for many developers in the months ahead. Beermann is quick to note the market is large enough for all the software developers to coexist.

“There are only a few companies left that develop this technology. It’s important to maintain connections and have good relationships with everyone involved.”

At Romax, the future involves ensuring their software remains at the cutting edge. They’re currently working on some long-term solutions to enable a larger proportion of mechanical engineers to have easy and affordable access to the tools they need.

“When Romax first entered the market with RomaxDesigner in 1993, it was a unique approach. Our challenge is to continue to innovate whilst delivering solutions that give our customers the competitive edge,” Poon says.

Still, the biggest concern for most developers comes back to the education and training needs of the engineers.

“A common trap in a great deal of engineering software use is thinking it will do the work of an engineer. With very few exceptions, software is still only a labor-saving device,” Fish says.

The problem isn’t just replacing the engineer; it’s getting each one on the same page. Fish says there’s still extreme confusion in comparative software programs. He states that even experienced gear engineers that make one different choice from a well-recognized standard can result in two completely different sets of analysis for the same set of problem parameters.

“It’s essential to understand this concept to improve software training on a global scale, especially when entering new and emerging markets,” says Fish.

As technology evolves, companies must be prepared to adapt to the ever-changing face of software development. While the programs of the early 1990s look prosaic by the standards in place today, one can only speculate what shortcuts and tricks will be available five years from now.

“The speed and scope of analysis and data in gear software is incredible,” Fish says, “but it will only ever be as good as the engineer using it.”

For more information:

Brad Foote Gear Works

1309 S. Cicero Ave.

Cicero, IL 60650

Phone: (708) 298-1100

Fax: (708) 652-4140

www.bradfoote.com

Dontyne Systems

1 Simonside

Prudhoe, Northumberland NE426JL

United Kingdom

Phone: +(44) 1661 833 828

Fax: +(44) 1661 523 614

www.dontynesystems.com

KISSsoft AG

Uetzikon 4

CH-8634 Hombrechtikon

Switzerland

Phone: +(41) 55 254 20 50

Fax: +(41) 55 254 20 51

www.kisssoft.ch

McLaren Performance Technologies Inc.

26555 Evergreen Rd., Ste. 900

Southfield, MI 48076

Phone: (248) 358-6039

www.mclarenperformance.com

Romax Technology

Rutherford House

Nottingham Science and Technology Park

Nottingham, Nottinghamshire NG7 2PZ

United Kingdom

Phone: +(44) 115 951 8800

Fax: +(44) 115 951 8801

www.romaxtech.com

See also Software Bits 2008