Modultherm Expands Capacity

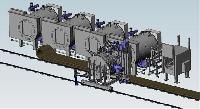

ALD and ALD-Holcroft Vacuum Technologies introduced a larger size of the ModulTherm vacuum heat treating system. The ModulTherm can now process load sizes of 36"x36"x72" with weights up to 7,000 lbs. Previously, the ModulTherm could only accommodate load sizes of 24"x30"x40" and 2,200 lbs.

"We've found justification for this size system based heavily in the wind power generation, bearing and construction equipment markets," says Klaus Loeser, vice president of new technologies at ALD Vacuum Technologies. "Too many opportunities have had to settle for atmosphere processing but could truly benefit from the attributes of vacuum. Now that possibility is realized."

The larger version system is available with high-pressure gas quenching, oil quenching, intensive quenching and interfaces to press quenching.

"Our ModulTherm concept has now taken another ‘growth step' in maturing as the industry standard for high production vacuum thermal processing. Now more than ever, the versatile nature of the ModulTherm is needed," says Bill Gornicki, vice president of sales and marketing for ALD-Holcroft. "As load sizes and part sizes increase, choices in quenching become an absolute necessity. In conjunction with last year's introduction of five separate quenching options, the ModulTherm is uniquely positioned as the standard for automated large load processing. High volume production of large components can now benefit from the significant value of low pressure carburizing."