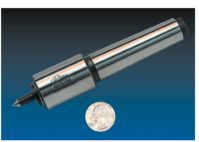

Riten Live Centers Engineered for Small Workpieces

Riten Extra-Light live centers are designed specifically to turn or grind parts weighing as little as two ounces. These parts are commonly found in the medical and aerospace industries, as well as the manufacture of small engine components. Parts of this size are often too light or too flimsy to turn the larger bearings found in typical live centers. This is a common problem, resulting in galling or excessive wear on the tip of the live center and/or damage to the part when the center fails to turn with the part. The Extra-Light live centers can turn parts at speeds up to 8,000 rpm while holding concentricity of ± .00005. This is achieved by using miniature precision angular contact bearings graded and matched at the factory to obtain the proper fit necessary to hold concentricity in high rpm applications. The small bearing head diameter and long spindle provide exceptional clearance for small workpieces, making the center an excellent choice for high production machine tools running light parts. Available from stock in 1, 2, 3 and 4 Morse Tapers, with customized designs quickly quoted by using the "Design Your Own" feature found at the website below.