MAG Plans Cryogenic Cooling Technology Lab at imX

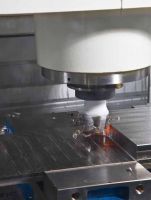

MAG delivers on the promise of imX Learning Labs by providing the first in-depth look at the capabilities of its patented new cryogenic tool cooling technology that uses liquid nitrogen - delivered through the cutting insert - to dramatically extend tool life or increase metal removal rates. Ideal for cutting titanium, inconel and CGI, cryogenic machining has also shown significant improvements in tool life and part quality for machining of composites, where it minimizes heat transfer to the resin matrix. Cryogenic machining's other cost savings, environmental and safety advantages will also be explained and analyzed. For example, by eliminating liquid coolant cryogenic machining results in clean finished parts - and chips - that do not need washing and drying. Slip hazards, part corrosion and machine maintenance are also reduced with the elimination of liquid coolant. MAG engineers will be on hand for Q&A as well as one-to-one discussions on how cryogenic machining can perform in specific applications or be implemented in any size shop.