Gear Expo Preview: Klingelnberg Booth 323

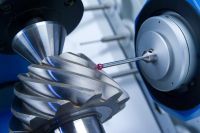

With the acquisition of the core business of Höfler Maschinenbau GmbH in 2012, Klingelnberg expanded its product portfolio with the addition of gear manufacturing machines for cylindrical gears, thereby strengthening its position as a single-source system supplier. The company's origins date back to 1863. In 1993, Oerlikon Geartec AG in Zurich was acquired and a new generation of bevel gear cutting machines, the C-Series, was developed. Within this product range, Klingelnberg introduced the dry-cutting process for spiral bevel gears in 1997. The service offering also includes machines for grinding, lapping and testing of bevel gears. The Klingelnberg precision measuring centers (P-Series) are used for dimension, form, and position measurements of gears and axially symmetrical components, such as tools, gears of all types, and gear components measuring several meters in diameter. During Gear Expo, Klingelnberg will be exhibiting the P 40 precision measuring center for the automotive, aviation, precision engineering and industrial construction industries. The P 40 offers a maximum workpiece diameter up to 400 mm, weight up to 300 kg and a vertical measuring range up to 550 mm. Additionally, it offers gear measurements as well as dimension, shape and position of axially symmetrical high-precision components of any kind, roughness measurement on tooth flanks; manifold options for testing of drive components in the automotive industry such as: clutch gears, sprockets, beveloid gears as well as camshafts and crankshafts; maximum precision and repeatability of measuring results; excellent mechanical basic precision and modern compensation strategies and easy operation with a graphical user interface.