Gleason Introduces New Bevel Gear Lapping Technology

Gleason Corporation recently announced SmartLAP, a technology for lapping bevel gear sets, with increased productivity, control and data collection.

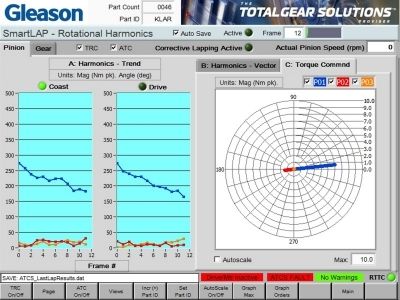

Available on the Gleason 600HTL Turbo Lapper Hypoid Lapping Machine (both new and as a field retrofit), the SmartLAP system combines a unique, yet simple gear spindle design with real-time motion-error measurement. It brings dynamic lapping forces under active servo control. The instantaneous tooth-to-tooth forces are no longer just a function of incoming part quality and passive physics but are instead actively modified by this smart mechatronic system to consistently improve DIN/AGMA part quality.

These enhanced dynamics also enable higher productivity without compromising quality. Pinion speeds and gear torques can now be increased by 30% or more without introducing the spacing errors that previously prevented faster cycles. The system also compensates for workholding run-out errors, making production less sensitive to tooling conditions. In addition, the tester-like data that is collected is displayed during the lapping process, giving users real-time insight into the process.