IMTS 2016: Oerlikon Balzers (W-2380)

Balinit Altensa

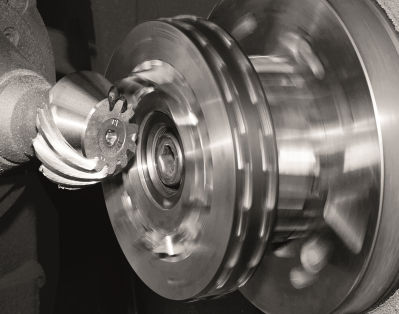

The Balinit Altensa is the newest product in the successful AlCrN family and it stands out especially through its wear resistance and hot hardness. In light of the market demand for ever higher machining speeds, the coating properties at high temperatures were specifically targeted for optimization. "Essentially, we further reduced the thermal conductance and improved the hot hardness of the coating by a good 20 percent," explains Wolfgang Kalss, head of marketing and product management for cutting tools. This has led to even higher resistance to crater wear, which can occur particularly at high service temperatures and reduces the useful life of the tool.

Moreover, the abrasive wear resistance was optimized by about 35 percent as was the oxidation resistance. This reduces the flank wear at moderate and high cutting speeds and it yields a longer tool service life, even with dry machining. The bottom line is that the numerous improvements in layer development enable considerable productivity gains with longer tool lifetimes, significant performance boosts at the highest cutting speeds for all substrates (PM HSS, MC90, carbide) as well as higher cutting speeds and feeds. Customer tests with various gear-cutting applications yielded corroborative results.

The versatility of Balinit Altensa is also proven in lubricated machining, in which initial results demonstrate a significant increase in service life.

Tests by an automotive supplier demonstrated that productivity can also be clearly improved for carbide stick blades. At a cutting speed increase of 35 percent to vc=200 m/min, a 30 percent improvement in service life was also achieved at the same time. Another automotive supplier tested coated HSS shaper cutters (diameter of 130 mm) in lubricated machining and the tools lasted 140 percent longer.