Third Wave Systems AdvantEdge Software Expanded to Include Gear Machining

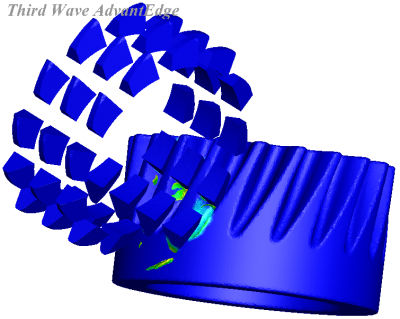

Third Wave Systems has successfully developed and simulated the complex processes involved in spiral bevel gear machining. With this AdvantEdge Gear Machining release, Third Wave Systems added the ability to simulate both single and continuous processes with both generating and non-generating motions.

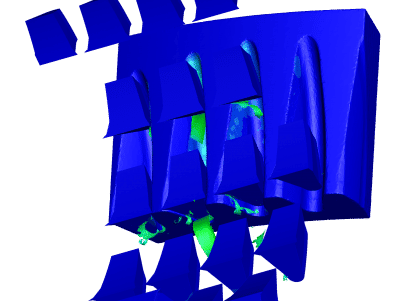

This builds upon the current capability to simulate cylindrical hobbing (v1.0) with the first release and allows the user to: simulate and analyze cutting process and chip formation; reduce manufacturing costs through tool life and material remove rate improvements; improve gear quality by identifying chip formation problems and the heat and stress added during machining to increase development ROI and reduce engineering effort; and utilize trial-and-error prototype testing.

The AdvantEdge Gear Machining v1.1 is based on AdvantEdge v7.3 to ensure accurate, validated results. This version includes additional functionality for easily entering process kinematics with industry standard language, advancements in initial meshing to generate in-cut mesh, a robust engine for large problem sizes and post-processing capabilities.

With this release the user will be able to: design and create in-cut gear geometries for generating or non-generating motion and either single or continuous indexing processes; use automatic meshing parameters to enable fast setup for non-generating motion and the ability to turn them off for our advanced users; import a STEP tool as a solid body or inserts only; and set standard materials for the gear (Pyrowear, AISI 9310, 4140 and 1020) and tool (Carbide, HSS).

"We have been receiving requests from the industry for many years to simulate gear machining with AdvantEdge and can't wait for our customers to begin using it to increase tool life, decrease cycle time and get their innovations into production faster," Kerry Marusich, Third Wave Systems' president, said.

The v1.1 release comes after the v1.0 release that included cylindrical hobbing. Several enhancements were added to allow for a more efficient simulation setup. In initial meshing, the user is able to design, generate and truncate the in-cut cylindrical gear geometry, which enables simulation at exactly the location of interest and only the section of gear which is important. Due to the custom nature of hobbing tools, the tool is required to be imported as a solid model and can be an indexable or solid tool.

During development of this capability, Third Wave Systems formed an industry group of gear machining experts to ensure that AdvantEdge Gear Machining v1.0 was focused on commercial application and industry needs. In addition to industry input, these capabilities were developed with the guidance and SBIR project funding from NAVAIR.

During the Phase 2.5 SBIR project, Gear Hobbing Predictive Model, Third Wave Systems successfully demonstrated and transitioned its modeling of gear machining processes for the Navy to predict and improve residual stresses and distortions while reducing the overall cycle times and costs for transmission gears.