Liebherr Develops Apps to Support Smart Automation

To support reliable production, the Automation Systems division of Liebherr has developed a range of four applications that support Industry 4.0 initiatives. A control system, LMS 4.0 (Liebherr Manufacturing System), permits customers to choose individually configurable software packages which meet their requirements for 4.0 applications.

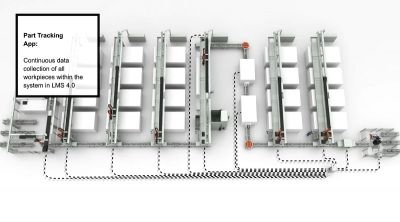

The four packages include: the Production Schedule App (PSA), which users can manage production orders and processes, the Part Tracking App (PTA) for logged part tracking in an assembly line and the Production Monitoring App (PMA) for recording production and operating data. There is also an app for the display of the machine status on a large screen or smartphone. Others are currently being developed, such as the Predictive Planned Maintenance (PPM) app.

The PTA (Part Tracking App) logs the workpiece data in a production cell before each workpiece loaded into the system, thus guaranteeing a reliable process. Users can easily adapt and freely configure the data structure with an Excel template. In this structure they can also define workpiece lists, based on priorities. Here, for example, they can generate workpiece lists which can be filtered as desired and offer possibilities for quality inspection.

Via the PSA (Production Schedule App) the workpiece flow and the production orders can be determined. This app also includes production order management. Here the operator can create production orders for loading unmachined parts, which contain part types, quantity, and delivery date. The system can then process these orders statically (according to sequence) or dynamically (according to delivery date).

The operation and production monitoring of the line is effected via the PMA (Production Monitoring App). Here all operating and production data of each station is recorded and can be evaluated accordingly. This way system availabilities and downtimes can be determined and visualized. With this data, weaknesses in the system can be detected and then optimized.

The software application PPM (Predictive Planned Maintenance App) allows for intelligent maintenance planning and can generate maintenance logs. The self-learning system registers the wear curves of the individual stations and creates intelligent maintenance planning in order to reduce and plan downtimes.

Large screens as well as mobile end devices are considered for the display. They are all controlled via the Info Board App. As a result, the user can have the operating states displayed on the machine - cell - station - component, call up workpiece counters, and perform remote monitoring.