Southtec Preview: EXSYS Tool, Inc.

EXSYS Tool, Inc. will offer attendees at Southtec the chance to experience its comprehensive range of tooling technology for turning machines and innovative gearbox solutions at the Greenville Convention Center in Greenville, South Carolina, October 22-24. Visitors to Booth 1829 will have the opportunity to learn how EXSYS’ modular toolholding solutions and EPPINGER’s gear-making expertise offer exceptional cost-savings and greater manufacturing efficiency.

In addition to its PRECI-FLEX modular toolholding system, which speeds turning center tooling changeovers and improves productivity with longer tool life, EXSYS will showcase the DECO-FLEX tooling interface, which adds flexible precision for small-part manufacturing and includes holders for all generations of Star CNC brand Swiss-style machines. EXSYS will also highlight EPPINGER gear solutions and their German-made precision, including standard spiral bevel, planetary, planetary bevel, hypoid and cycloidal gearboxes, along with custom gear-making services.

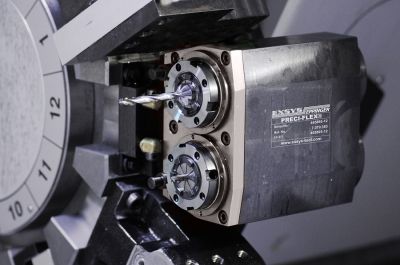

EPPINGER PRECI-FLEX modular toolholding system

The compact PRECI-FLEX modular toolholding system is the first of its kind on the market that utilizes the ER collet pocket and includes a single base holder with multiple tooling adapters. PRECI-FLEX's conical and flat-face planar interface allows the use of either an adapter or a standard ER collet and enables collets, endmill holders, expanding collet chucks and shrink-fit tooling to be mounted on a single-base holder.

Double-collet PRECI-FLEX holders

Within the PRECI-FLEX modular tooling system, the revolutionary two-collet chuck delivers up to 10,000 rpm with a 1:1 ratio and 20 N-m of torque to boost productivity and achieve excellent surface finishes on machines with optional 10,000 rpm machine spindles, Y-axis functionality and standard BMT turrets. Designed for Mazak QUICK TURN and QTU Series Turning Centers, these double-collet holders feature an EXSYS/EPPINGER Compensating Clutch with a floating coupling between turret drive motor tangs and toolholders to automatically compensate for any misalignment, reducing vibration and tool chatter to produce longer tool life and better parts.

DECO-FLEX tooling interface

The high-accuracy DECO-FLEX tooling interface offers unmatched flexibility, precision and cost savings. Its minimal envelope dimensions make it ideal for use on turning and milling centers with limited working areas. The compact design ensures maximum torque transmission and rigidity for high machining accuracy, productivity and machine-tool efficiency.

DECO-FLEX holders for Star CNC brand Swiss-style machines

Along with mounting adapters, the DECO-FLEX interface includes holders mounted into and dedicated to Star CNC brand Swiss-style machines. These products enable high-volume shops to run multiple toolholders in a single tool position, reduce tooling changeover times significantly and increase tool rigidity for longer tool life on these machines. The DECO-FLEX system adapts to every Star machine model.

EPPINGER gear solutions

German-made EPPINGER gearboxes and custom gear-making services offer precision and flexibility for a wide variety of industries. BT (bevel torque) and BM (bevel maximum torque) spiral bevel gearboxes provide minimized tooth clearance and optimal transmission properties with precision axes and bearing seats as well as GLEASON bevel gears to withstand high loads. PE (planetary eco) and PP (planetary precision) planetary gearboxes combine low backlash, high efficiency, shock resistance and a high torque-to-weight ratio in a modular design that incorporates ground gears and precision gear components.

BP (bevel planetary) gearboxes pair BT and PE features in an innovative design with smooth-running components and constant backlash control. HT-type compact, robust hypoid gearboxes suit specific and highly dynamic applications, with a specially developed aluminum mono-block housing, high-precision bearing seats and an integrated input shank. High-transmission cycloidal gearboxes offer integrated support bearings and high-overload capacity for applications that demand the utmost stiffness, performance and efficiency.

For custom applications, EPPINGER applies more than 20 years of experience to develop and manufacture virtually any gear design, with crown gear diameters ranging from 0.4 mm to 330 mm, depending on transmission ratio.