EMO Hannover 2019: DMG MORI

DMG MORI (Hall 2) will highlight a variety of technologies at EMO Hannover including automation, digitization, additive manufacturing and more. Here are a few highlights:

Automation

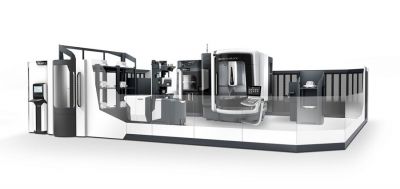

The WH CELL and WH FLEX are just two of the 27 automation solutions that DMG MORI will be showcasing at the EMO. After the successful start of DMG MORI HEITEC at the end of 2017 several dozen projects could be realized. In future DMG MORI will offer all the machine tools in its portfolio with automation solutions, in order to meet the massive and steadily increasing demand. Another highlight among the numerous automation solutions in Hall 2 is the DMU 65 monoBLOCK with the new AGV (Automated Guided Vehicle), a stand-alone system for pallet automation. This innovative solution offers a flexible automation layout with free access to the machine and an intelligent safety concept for human-machine collaboration.

Intelligent Production

For DMG MORI “connectivity” constitutes one of the core features on the path to the digital factory, because only open interfaces and standardized communication protocols can ensure future-oriented end-to-end integration and interoperability of machines and processes. That is why in future all new machines from DMG MORI will be connectivity compliant in their standard versions at no extra cost. The new IIoT interface supports both the standard MQTT and MTconnect protocols as well as the new umati (universal machine and tool interface) branch standard based on OPC UA.

DMG MORI will be presenting the new CELOS APPs in line with its focus on integrated connectivity. The new APPLICATION CONNECTOR, for example, enables the operation of all web-based applications directly via CELOS. So direct interaction with MES or ERP systems is possible as is access to specialized customer applications. The new JOB IMPORT feature enables orders to be imported directly from MES or ERP into the CELOS JOB MANAGER.

Maximum customer benefit is also the focus of the new digital customer portal my DMG MORI. DMG MORI brings together the expectations of its future-oriented initiatives “Integrated Digitization”, “First Quality” and “Customer First”. The result is a unique online portal for interactive cooperation between DMG MORI and its customers.

Additive Manufacturing

The powder bed machines in the LASERTEC SLM series are designed for the productive manufacturing of complex workpieces. The precision of selective laser melting enables the realization of complex geometries that would be impossible to produce with conventional methods. The series includes the successful LASERTEC 30 SLM 2nd Generation with a 300 × 300 × 300 mm build volume and the LASERTEC 12 SLM, which owes its unique accuracy to its focus diameter of just 35 µm. The fast powder change using the rePLUG powder modules takes in less than two hours. The OPTOMET software enables automatic calculation of all process parameters within days instead of months. Layer thicknesses, for example, can be calculated freely, which in turn enables a faster and therefore also more productive build.

As a powder nozzle machine developed primarily for larger workpieces of up to ø 500 x 400 mm and weights of 600 kg, the LASERTEC 65 3D hybrid unites the build of workpieces using laser deposition welding and 5-axis simultaneous milling operations in a single setup. This hybrid approach enables the production of highly complex geometries in finished-part quality as well as the use of different materials in one workpiece. DMG MORI will present the LASERTEC 65 3D hybrid at the EMO with a series of monitoring and calibration sensors, which boost process reliability and further enhance the quality of additively produced components. Furthermore, laser deposition welding is also suitable for the repairing of tools. DMG MORI will be showcasing an automated concept for this at the EMO.