Hainbuch Offers 2-Jaw Module System

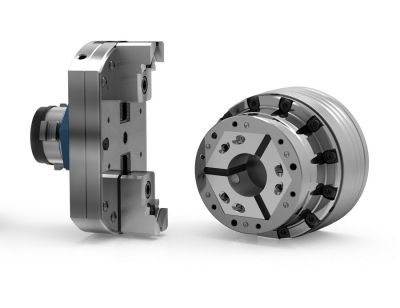

Hainbuch recently introduced the 2-jaw module, a small alternative to the large centric vice. Round workpieces are clamped from the outside with clamping heads (collets) within the collet chuck. Larger diameter workpieces, beyond the capacity of the collet chuck, can be clamped with the 3-jaw module. For cubic parts that are positioned centrically on machining centers and milling machines, the new 2-jaw module is now an option. Changeover from clamping round parts to cubic ones is possible in less than two minutes.

The 2-jaw module can handle turning applications up to 1,500 rpm. The 2-jaw and 3-jaw module use the Hainbuch collet chuck as their base. Changeover is possible without removing the collet chuck and realignment thanks to Hainbuch’s Centrex quick-change interface.

Hainbuch’s modular solution, consisting of a chuck and jaw module, no longer compare to the large and heavy vises that are found in many shops and whose size is more of an obstacle than an advantage. As is often the case, the workholding is much larger than the part to be machined so interference is an issue. Special, longer tools are then needed and there’s a risk of a costly collision. The Hainbuch modular system, on the other hand, is just as efficient and flexible as your multitasking machine tools are today.