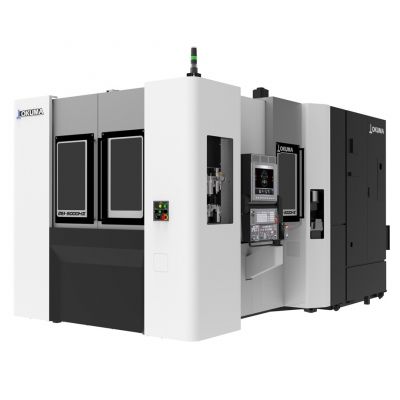

Okuma HMC Improves Productivity

MB-5000HII from Okuma is a high-speed, thermally-stable horizontal machining center that offers quick acceleration, short tool changes, and high power to improve productivity. This machine's powerful cutting capabilities and high-speed automation increase productivity and reduce cycle time by up to 25 percent, while the 20 percent smaller footprint maximizes valuable shop floor space.

The MB-5000HII has a new spindle with high rigidity and high torque which makes possible heavy-duty cutting of steel at 704 cm³/min (S45C) with an end mill.

With excellent chip discharge maintenance and super-minimal machine structure, Okuma's Thermo-Friendly Concept and OSP-AI Machine Diagnostics are onboard to deliver the stable machining accuracies required for long periods of unattended operation. At the same time, the footprint has been reduced by 10%, to achieve a highest-class level of floor space productivity (20% improvement over the previous machine).

The MB-5000II, while being well equipped to handle a wide range of applications from fast machining to heavy cutting, this HMC will meet the increasingly stronger need for the labor-saving and unmanned operations expected in the future.

The video link below shows the machining center producing a gearbox housing.