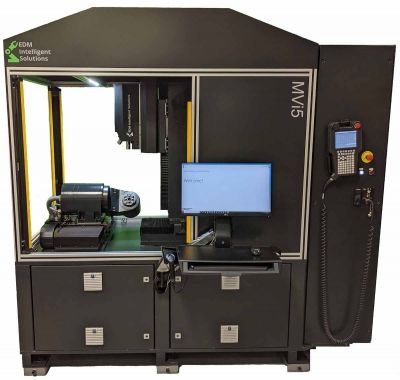

EDM Intelligent Solutions Offers 5-Axis 3D Metrology Center

EDM Intelligent Solutions (EDMIS) is pleased to announce the release of their new MVi5 – 5-Axis 3D Metrology Center joining FANUC CNC controls with advanced 3D metrology sensors to create an industry ready multi-sensor metrology and measurement platform. The company provides a unique level of expertise for the automation and industrial metrology requirements of OEM and research and development customers within the major aerospace, automotive, communications, defense, medical, and scientific industries.

EDM Intelligent Solutions automation group has developed a unique, 5-Axis 3D Metrology Center based on a machine tool motion system with fully integrated high-resolution 3D metrology sensors. Utilizing industry proven FANUC CNC controls and servomotors, the MVi5 offers the reliability and long-life performance that users in the aerospace, automotive, mechanical engineering, medical, plastics, and semiconductor technology industries have come to trust.

The robust machine tool base houses a top-of-the-line motion system with linear travels of 300 mm on the X, Y and Z axes along with integrated glass scales on each. The heavy-duty rotation and tilt unit features an enhanced payload of 20 kg with a B-Axis tilt range of +/-120° and continuous C-Axis rotation of 360°, with both axes having integrated absolute encoders.

Advanced 3D metrology sensors featuring measurement speeds of up to ≤ 1.7 million points per second and high-resolutions of 10 nm allow the MVi5 to measure form, distance, height, surface roughness, true position, scan vs. CAD model differences and scan vs. scan differences all in one rugged multi-sensor platform that is ready to be installed directly on the manufacturing production floor.

The need for hands on, complex programming of the measurement and inspection tasks have been virtually eliminated and replaced with a user friendly, menu-based programming interface found in the Foundation Programming Environment from EDMIS. Customized 3D model-based measurement and inspection programs are automatically generated off the 3D solid model design of the part to be inspected. The user simply uploads the solid model, selects the areas to measure and a program is created. Offline measurement and inspection programming is also offered through integration with various CAD/CAM software packages common within industry. Operation of the MVi5 5-Axis 3D Metrology Center is quick and simple via the touch screen optimized EDMISi human machine interface with native barcode compatibility. User access controls and permissions allow operators to only select and run approved inspection programs while Engineering and Administration staff have full access to create and modify programs and to administer all features and functionality of the machine.