Noncircular Gears

The unicorn of machine technology

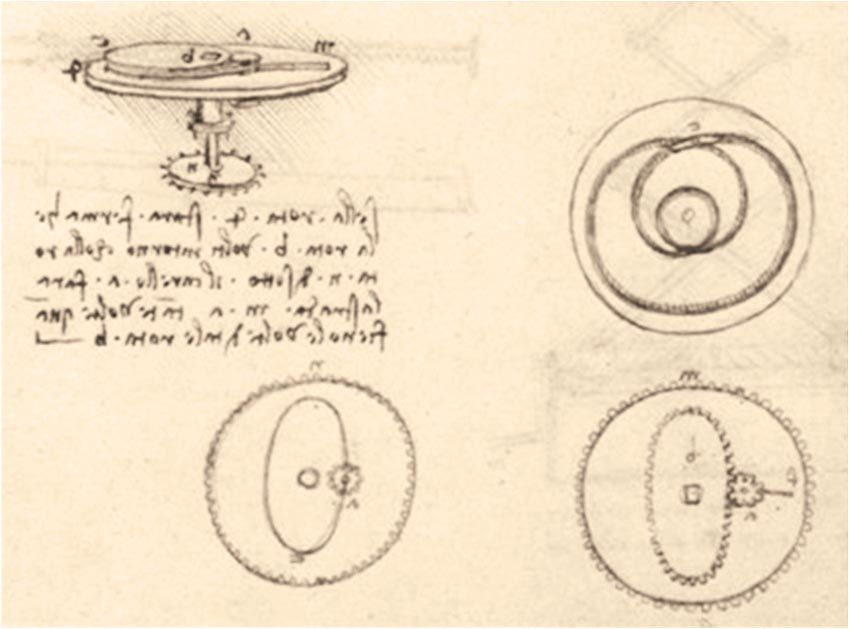

Noncircular gears are not a mere mathematical curiosity with limited practical utility. They were first sketched by Leonardo da Vinci around 1500 and have since found their way into a variety of useful applications. In the 18th century, noncircular gears were used in flow pumps, clocks, music boxes, toys, and other devices. Early publications on the gear type in the 19th century by Hamnet Holditch (1842), Henry T. Brown (1871), and Franz Reuleaux (1875) helped evolve the field of kinematics. First introduced by Uno Ollson in his book Non-Circular Bevel Gear in 1959, the noncircular bevel gear has remained obscure due to the complex geometry. Even though more and more publications are available on noncircular gears, the knowledge is, especially compared to cylindrical gears, still very limited. But in the last decade, there has been an increased interest in the field of noncircular gears due to certain advantages they have over circular gears.

In 2009, Cambridge University Press published a comprehensive overview titled Noncircular Gears: Design and Generation by Faydor L. Litvin, Alfonso Fuentes-Aznar, Ignacio Gonzalez-Perez, and Kenichi Hayasaka. The book applies modern theories of gearing to the design and manufacture of the main types of noncircular gears: conventional and modified elliptical gears, eccentric gears, oval gears, gears with lobes, and twisted gears. It even goes so far as to speculate methods of generating noncircular gears by developing methods akin to those applied to the generation of circular gears and aims to extend the application of noncircular gear drives in mechanisms and industry.

As additive manufacturing, novel alloys, and other technologies mature they will allow greater manufacturability and exploit the unique mechanical features noncircular gears have to offer. Historical applications have included textile machines, nonlinear potentiometer drives, Geneva indexing devices, continuously variable transmissions (CVTs), window-shade panel drives, mechanical presses, flow meters, and high-torque hydraulic engines. A circular gear set is designed to roll together without slip and optimized to transmit torque to another engaged member with minimum noise and wear and maximum efficiency, whereas a noncircular gear’s main objective might be ratio variations, axle displacement oscillations, and other modifications and configurations to achieve dynamic forms of utility. Because of the complex geometry, noncircular gears typically have a straight-toothed elliptical form and are manufactured by molding or sintering as opposed to conventional forms of gear generation.

The design and manufacture of noncircular gears are one of the unicorns of machine technology. Due to the limited technological capabilities of traditional machines and tools, past manufacturing methods were unable to calculate the assumed shape of the tooth line and its profile. Modern manufacturing methods using CNCs allow for the generation of noncircular gears. Development in the field has been slow due to the complicated nature of equations describing noncircular gears which have made their analysis virtually impossible without the aid of computer technology.

Recently, concurrent with the development of more sophisticated design and manufacturing technology, research on this gear type has been reinvigorated. Academics have synthesized the pitch cones for elliptical bevel gears; investigated a tooth profile generation method for noncircular straight bevel gear and high-order involute modified noncircular bevel gear; established a mathematic model for noncircular straight bevel gear based on the spatial meshing theory; and investigated noncircular bevel gear with concave pitch curve. Noncircular gears are increasingly used in practice and further research will eventually examine the geometric and kinematic accuracy, as well as the strength, of noncircular gears manufactured through different methods. Noncircular gears are designed to have variable output loads and speeds. It is also possible to design them with variable center distances. Compared to cylindrical gears, the main advantage of noncircular gears is their potential for EVs, robotics, automation, and other industries where the variable transmission function could be a revolutionary solution.