Dontyne Introduces Latest Gear Design Services at IMTS 2022

Dontyne Gears is looking forward to IMTS to promote the company’s range of gear design services developed during COVID restrictions. Dontyne Gears continues to work with companies to complete design projects including CAD models and drawings if required. They recently purchased an Okuma Genos 5-axis to add to the Osaka Siemitsu high accuracy gear inspection center already in house for prototyping. As well as cylindrical gears it is possible to produce straight, spiral, and hypoid bevels. The work is facilitated by using Gear Production Suite from Dontyne Systems to generate tool forms, G-code, and inspection protocols which can be used by the machines.

Dontyne has designed and constructed a test rig to bench test cylindrical gear system. This is specialized to the higher ratio ranges typically found in EV applications, but they’ve worked on custom models for some clients to test their own applications. The test rigs are now offered as a product line of Dontyne. Offering a more complete development service with at least a basic test validation from one source keeps costs and lead times down encouraging companies to enter a development program with lower risk levels.

It has been possible to complete R&D projects including production not available onsite by collaborating with companies with specialist knowledge in forging, grinding, and sintering. Dontyne has worked on the design of bevels with increased bending strength and reduced production times by making dies on 5-axis machines, grinding of non-involute gear forms, and improved performance characteristics using powder metal gears.

Dontyne has entered into a sales agreement with Renishaw Inc. to offer their own inspection solution using their Equator device called Dontyne Integrated Gear Gauging Solution (DIGGS). The hardware works with Dontyne software and support services to remove bottle necks caused by dependence on measurements in temperature-controlled environments. Measuring cycles have been reduced to less than 30 seconds in some cases while maintaining a realistic level of accuracy for production. A simulation added to the GPS software can establish inspection type, time, and check for interference of the probe at the design stage prior to production. This is only for cylindrical gears at this point, but a bevel gear option is in development. Dontyne will be demonstrating this during IMTS.

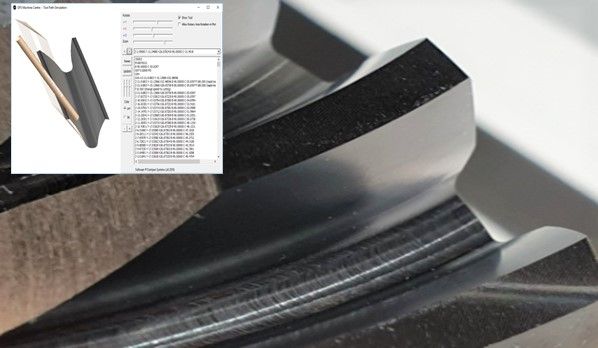

Dontyne Systems will promote the latest developments of GPS at IMTS. In recent years, the company has concentrated strongly on linking gear design to tool design and manufacture. An important part has been to produce complex gear forms at low cost on flexible multi axis machines. As wells as cylindrical gears, it is possible to produce straight and spiral bevels using standard end mill tools. The software has been adopted by many companies in the UK and beyond for low volume production and for R&D. A hypoid design option has been added for the current GPS 5.7 release. Interfacing to the Equator and Sprint devices from Renishaw has enhanced the ability to create a closed loop control system at low cost compared to dedicated gear machines.

Dontyne has also improved the hob/grind simulation for GPS 5.7, already in wider spread use worldwide, to manufacture Beveloid gear forms compatible with grinding machines such as those produce by Reishauer AG. The hob/grind functionality in GPS has been integrated to the Romax Technology system model software to confirm correct gear generation and define stable and safe production tolerances at the design stage. An interface exists from system model software of both Romax and Ricardo to GPS this to enable user to quickly and accurately export data to tool makers using Dontyne’s software whether in house or outsourced. The manufacturer can quickly check and take corrective action if required. The correction can be updated in the client while still in the design stage. There are significant savings to be made in avoiding mistakes during production.