Marposs Announces Flexible Laser Gear Inspection System

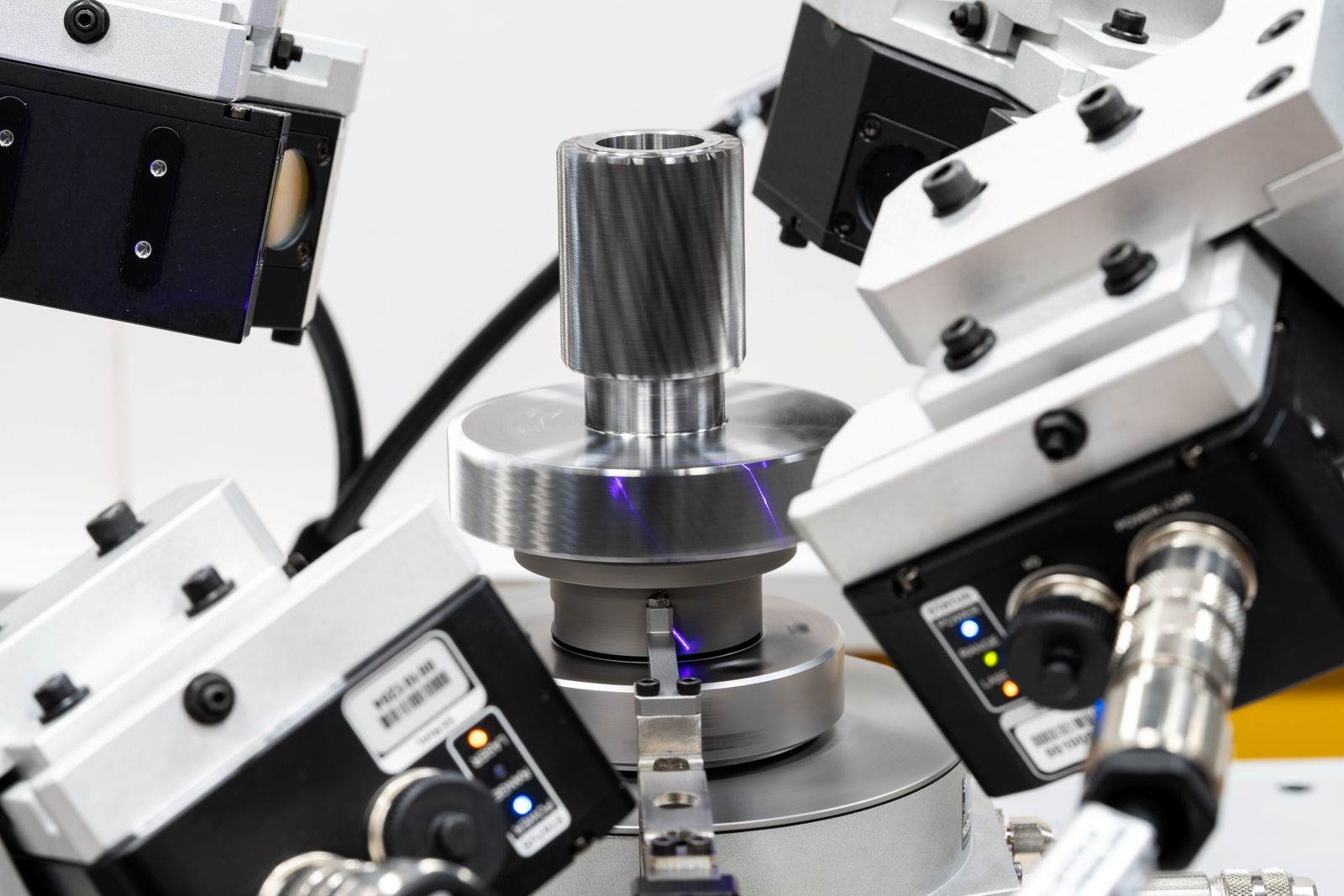

Marposs, a global leader in measurement, inspection and test technologies, has announced its new M62 Laser Profiler for Gear Inspection, using laser profile sensors and the optical triangulation principle. As compared to dedicated gear gauging systems or gear laboratory machines, the use of laser technology in the profiler enables it to easily adapt to inspecting a variety of gear sizes and shapes in a very short time.

The laser profilers project a laser line on the gear at a specific angle, collecting data to generate the entire Z-X profile through an image sensor placed behind the optical receiver. The gear is then quickly rotated 360° to collect data points from movement along the Y axis, which is combined with the Z-X profile to create a complete 3D reconstruction of the part, made possible through specific software algorithms. The system then executes the requested measurement and inspection tasks. Line operators can easily review images and navigate to the desired level of detail to identify any anomalies.

The Laser Profiler can inspect odd or even toothed helical and spur gears with external diameters from 30 ÷ 300 mm and heights ranging from 15 ÷ 40 mm with the capability to measure characteristics having tolerances up to 5-10 µm. With a cycle time of approximately 40 seconds, it has the precision to accurately inspect micro-geometric features including:

- Profile Crowning (Cα)

- Profile Slope Deviation (fhα)

- Total Profile Form Deviation (Ffa)

- Flank Line Crowning (Cβ)

- Helix Slope Deviation (fhβ)

- Total Helix Form Deviation (Ffβ)

Like other gear measurement solutions from Marposs, this non-contact system can be interfaced with Marposs electronic measurement display units, like the powerful E9066 industrial computer provided with a sophisticated graphic display algorithm for gear analysis as well as comprehensive statistical calculations.