Gear Skiving in Focus: esco Presents New Module for Feasibility Studies and Comprehensive Software Platform ePP

esco, technology partner for process digitization in the gear and cutting tool industry, is expanding its software offering with the new eSkiving.FS module for effective feasibility studies in gear skiving. At the same time, the company is introducing ePP, a comprehensive software platform that includes eSkiving.FS to provide seamless support in all areas of the gear skiving process.

New eSkiving.FS software module

Gear manufacturers often need additional know-how and more transparency about the skiving process to avoid errors and lengthy optimization loops. With this in mind, esco has developed the eSkiving.FS software module, which enables users to validate and optimize gear manufacturing right at the beginning of the process chain. The new module is suitable for use in both gear development and gear production planning. eSkiving.FS offers all the necessary features for application-specific feasibility studies and enables efficient implementation of gear skiving as gear manufacturing process:

- Parameter-based generation of the gear geometry

- Simulation of skiving kinematics

- Generation of the basic geometry for the skiving tool

- Collision detection: import of surrounding component geometries through 3D or easy parameterisation

- Simulation of gear skiving in 3D ("virtual machining")

- Definition of the cut distribution and estimation of main machining time for skiving

- Output of the basic tool geometry and all relevant parameters for the detailed skiving tool design on the basis of the feasibility study

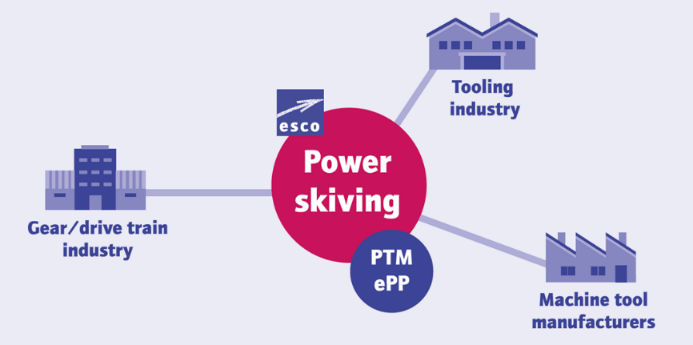

New ePP software platform

With the latest addition to its software offering, esco now provides a platform that allows all developers and users involved to access a common information base. The ePP software platform ensures seamless data communication throughout the entire skiving process and supports the successful introduction and implementation of gear skiving. With the launch of eSkiving.FS in November 2022, the ePP software platform comprises five seamless interlinked modules:

- eSkiving.FS (Feasibility Studies): module for conducting feasibility studies

- eSkiving.TD (Tool Design): module for tool design based on the manufacturing simulation of Skiving

- eSkiving.TA (Technology Analysis): module for the analysis of technologically relevant parameters (requires eSkiving.TD)

- eSkiving.AS (Application Support): module for application optimization on-site (requires eSkiving.TA)

- eSkiving.TP (Tool Production): module for the manufacturing of skiving cutters

"Connecting the dots": the ePP software platform ensures seamless data communication throughout the entire skiving process.