Analytical Determination of Range of Number of Teeth in Generating Non-Involute Tooth Forms Using Fixed Reference Profiles

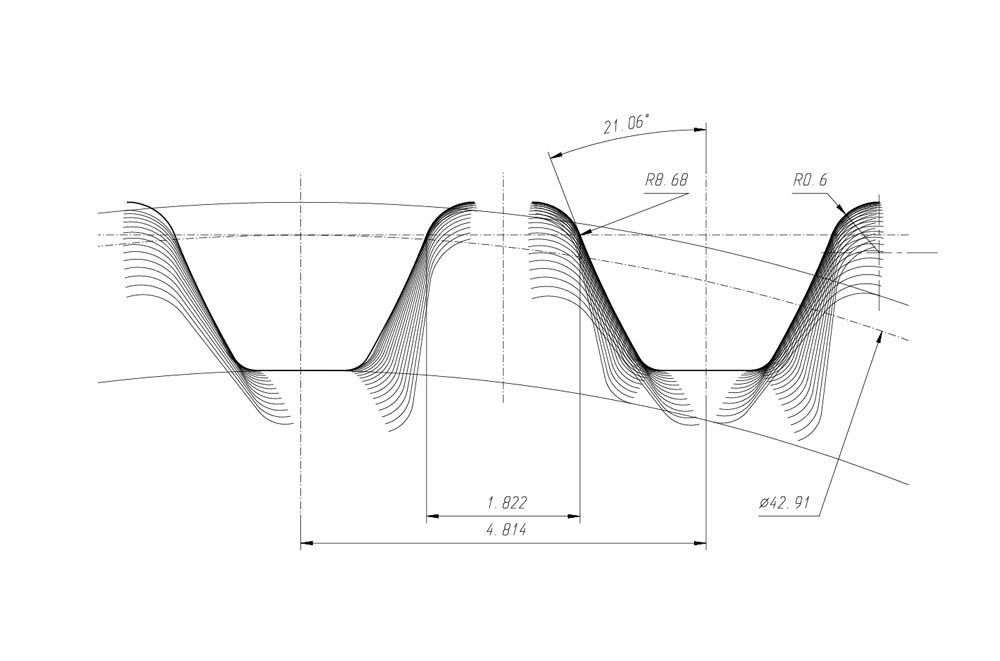

The standard ISO 17396:2017 specifies sizes and tolerances of pulleys for synchronous belt drives. The pulleys feature trapezoidal tooth profiles that can be machined with generating methods (such as hobbing). The profile is different for each pulley diameter. A reference profile, produced by a generating tool (such as a hob), can closely approximate the nominal tooth shape over a range of a number of teeth (Ref. 1).

The reference profiles for involute gears have straight-line sections that shape theoretically correct tooth flanks regardless of the number of teeth on the gear. On the other hand, a unique reference profile corresponds to the number of trapezoidal teeth on a belt pulley. That reference profile can be obtained for each pulley with methods described in Ref. 2, 3, 4. If imported into CAD software, it can be compared with other profiles, which were created for a different number of teeth on the pulleys. Tooth forms generated with fixed reference profiles can be found using the same methods, and the profiles can be compared with each other and against the specifications from the ISO standard. As these comparisons are usually done manually, they may take a significant amount of time and effort.

When a reference profile suitable for generating the subject toothing is obtained, a tool’s profile can be derived from it, which may include process-related modifications. In the case of hobbing, these modifications may be necessary for several reasons, including tool-workpiece kinematics of two bodies rotating around skew axes (Ref. 2), and local cutting conditions which change along the cutting edge having an influence on the final shape of the gap being cut. A single tool can typically produce a single reference profile, therefore the act of selecting the reference profile or profiles required for a given task is a very important step in designing the manufacturing process as it has a direct and decisive influence on the costs. The methods based on manual comparisons of profiles in CAD software might not be efficient enough in some cases, so an analytical method needed to be developed to streamline the reference profile development process.

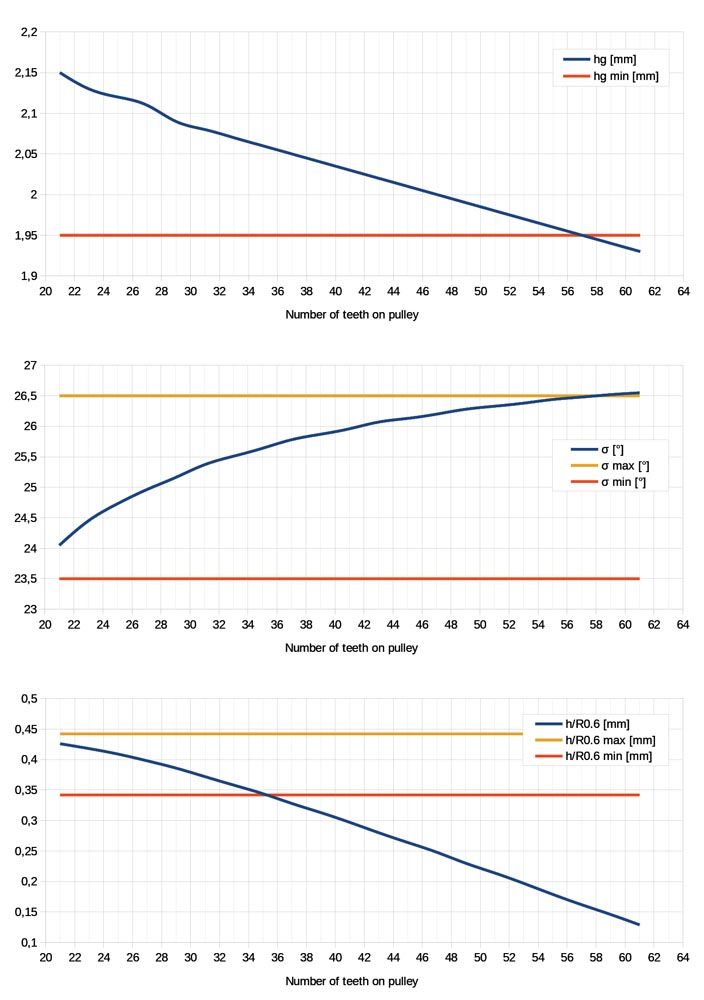

The toothed belt and pulley system known by the designation T, which has been selected as an example within this paper, was developed in the 1950s and standardized first in DIN 7721 (1977) and then in ISO 17396:2014 (Ref. 5). Here, in this case study, we check if a single hob can properly cut T5 profile pulleys with 25 and 30 teeth, and if so—define the range of the number of teeth covered by this hob. Standard tool designs indicate a range from 21 to 36 teeth (Ref. 6), 21 to 50 teeth (Ref. 7), and 21 teeth and more (Ref. 8).

Pulley Geometry

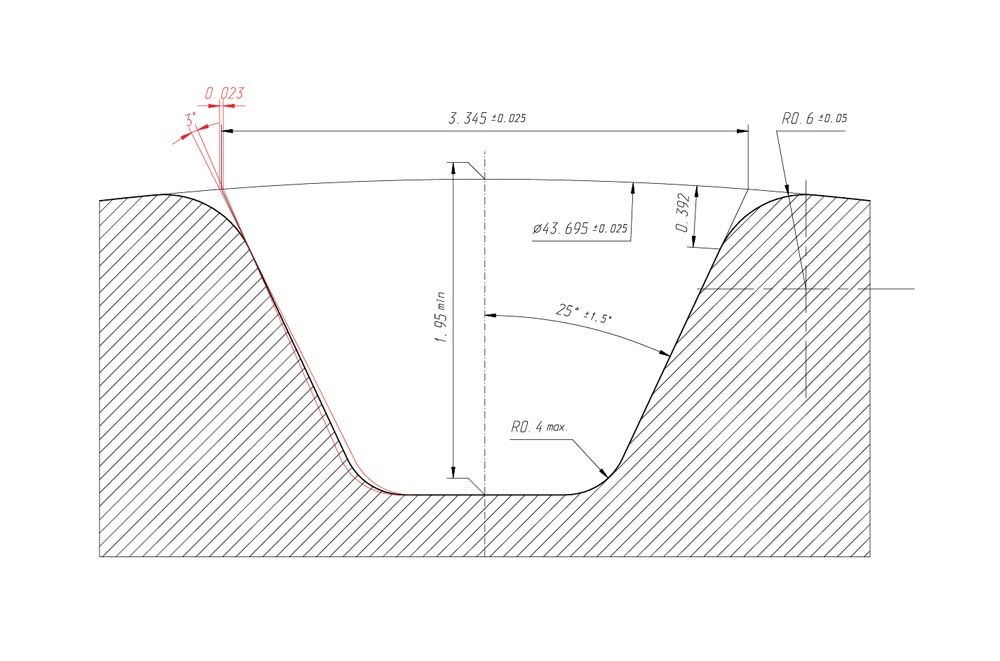

As the number of teeth to be considered first are 25 and 30, a T5 28-tooth pulley profile has been selected from the ISO 17396:2017 standard, and is shown here (in millimeters):

The specified flank angle tolerance is ±1.5 degrees. If constant gap width at points where straight flank lines end and rounding R0.6 mm begins was maintained, changing the flank angle within that tolerance produces changes of specified gap width 3.345 mm. The magnitude of these changes for each side is of the same order as the gap width tolerance (Figure 1—details drawn red). Furthermore, the specified gap width is dependent also on the tolerance of major diameter ϕ43.695 mm. To address problems resulting from these changes, it has been assumed that nominal values in the middle of respective tolerances will be used within the scope of this paper.